Newsletter Volume 9, Issue 4 December 2024

The Potential Use of Press-in Methods in the Offshore Renewables Industry

Chair: Stuart Haigh

Professor of Geotechnical Engineering

University of Cambridge, UK

Professor Ken Gavin gave the 2nd Keynote Lecture of the 3rd ICPE2024 on the Challenges and Opportunities of utilizing press-in piling for offshore renewables. Prof Gavin is perfectly placed to do this being Professor of Subsurface Engineering at TU Delft, an accomplished practicing Offshore Engineer and incoming president of the IPA.

It was highlighted that the ever-increasing size of offshore wind turbines, with current 15 MW models having towers around 200 m tall has led to extremely large monopile foundations being used with diameters now reaching 10 m. These extremely large foundations lead to extreme challenges for installation in the complex offshore environment. Typically, offshore foundations are driven to achieve the benefit of locked-in stresses within the ground but the cyclic nature of the driving processes can lead to decreases in capacity (especially in the short-term) due to friction fatigue as well as potentially unacceptable impacts on marine mammals due to noise and vibration which may need to be mitigated with costly techniques such as bubble curtains. Jacking of piles has been shown by many past researchers to provide capacities and stiffnesses similar to driving but without damaging environmental impacts. Jacking has also been shown to achieve a much greater proportion of ultimate pile capacity in the short term than driving, leading to potential benefits of being able to utilize pile foundations quickly after installation.

Prof. Gavin also described several other current challenges in offshore piling which would need to be addressed if press-in piling is to be utilized. Offshore wind-farms cover extensive areas and subsurface data may be sparse. Ground modelling is thus vital to ensure that the ground conditions at individual pile locations can be well estimated, but this may not prevent the impact of buried boulders which can be too small to be picked up on a site-scale survey but may have a substantial impact on individual piles.

Pile-run is another phenomenon which is causing significant problems in areas of South East Asia. Variable soil strength with depth can cause runaway of piles with the soil resistance unexpectedly being insufficient to support the weight of the pile and hammer leading to an increasing pile velocity. This can cause loss of equipment and potentially damage to piling vessels. Press-in piling should be less sensitive to this problem than driven piling as the process is essentially displacement controlled.

Other challenges in the offshore mirror those that have already been surmounted onshore including piling through hard soils and rock layers which may require the use of augering.

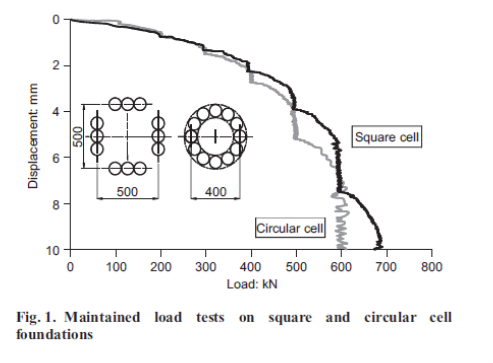

If press-in piling is to be utilized for offshore wind, techniques must be developed to install foundations using press-in techniques of a substantially greater size than are currently being installed onshore. Pressing in individual piles of this size may be impossible, but techniques to create composite foundations from multiple smaller piles as demonstrated by Yetginer et al (2006) may be a way forward to moving the advantages of the press-in piling method into the offshore sphere.

If press-in piling is to be utilized for offshore wind, techniques must be developed to install foundations using press-in techniques of a substantially greater size than are currently being installed onshore. Pressing in individual piles of this size may be impossible, but techniques to create composite foundations from multiple smaller piles as demonstrated by Yetginer et al (2006) may be a way forward to moving the advantages of the press-in piling method into the offshore sphere.

Reference:

Yetginer, A. G., White, D. J. & Bolton, M. D. (2006). Geotechnique 56, No. 5, 349-354

| << Previous | Newsletter Top | Next >> |