Newsletter Volume 10, Issue 2 June 2025

On-site Interview Report

Temporary embankment construction using the Combi-Gyro Method™ (Itami City, Hyogo, Japan)

Temporary embankment construction using the Combi-Gyro Method™ (Itami City, Hyogo, Japan)

Maki Kato

IPA Secretariat

▶日本語記事はこちら

|

Mr. Yuki Aoyagi SATO JUKI Corporation Mr. Aoyagi joined SATO JUKI Corporation in 2016. He has been working in press-in construction ever since. He supervises the foreman on this construction project. |

|

Mr. Junta Iwano SATO JUKI Corporation Mr. Iwano joined SATO JUKI Corporation in 2011. He has been working in press-in construction ever since. He supervises the operator on this construction project. |

Q1: Could you give us an overview of this construction project, including its background?

Mr. Aoyagi:

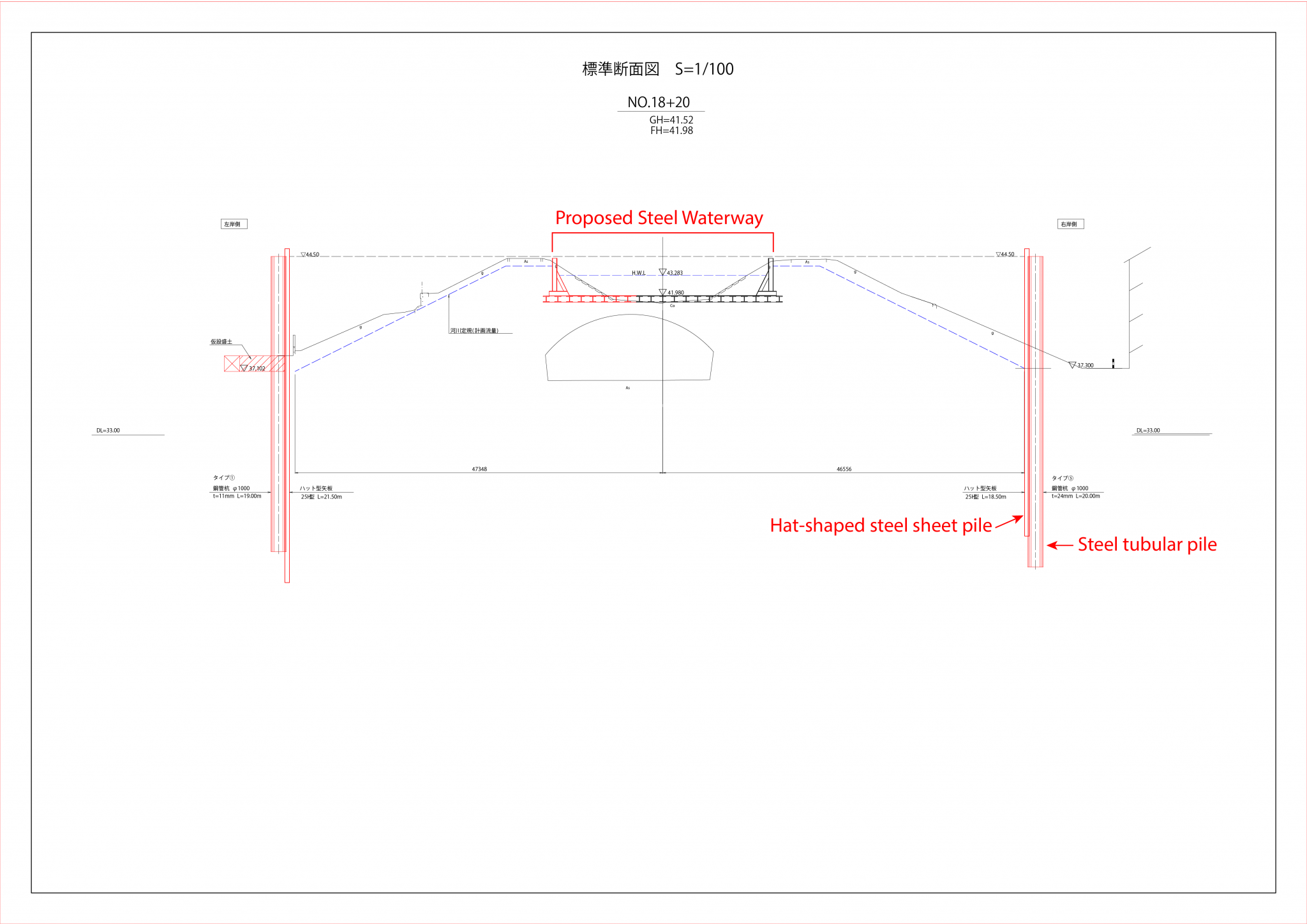

Ultimately, the plan is to reroute the river channel using a steel waterway, excavate the levee, rebuild the Aramaki Tunnel—which runs under the Tenjin River—as a box culvert, and then reinforce the levee. Right now, we are starting with the first phase of the project: installing a temporary levee. Since installing the box culvert requires full excavation of the existing levee, we’re constructing a cut-off wall outside the levee using the “Combi-Gyro Method.”

[Project Information]

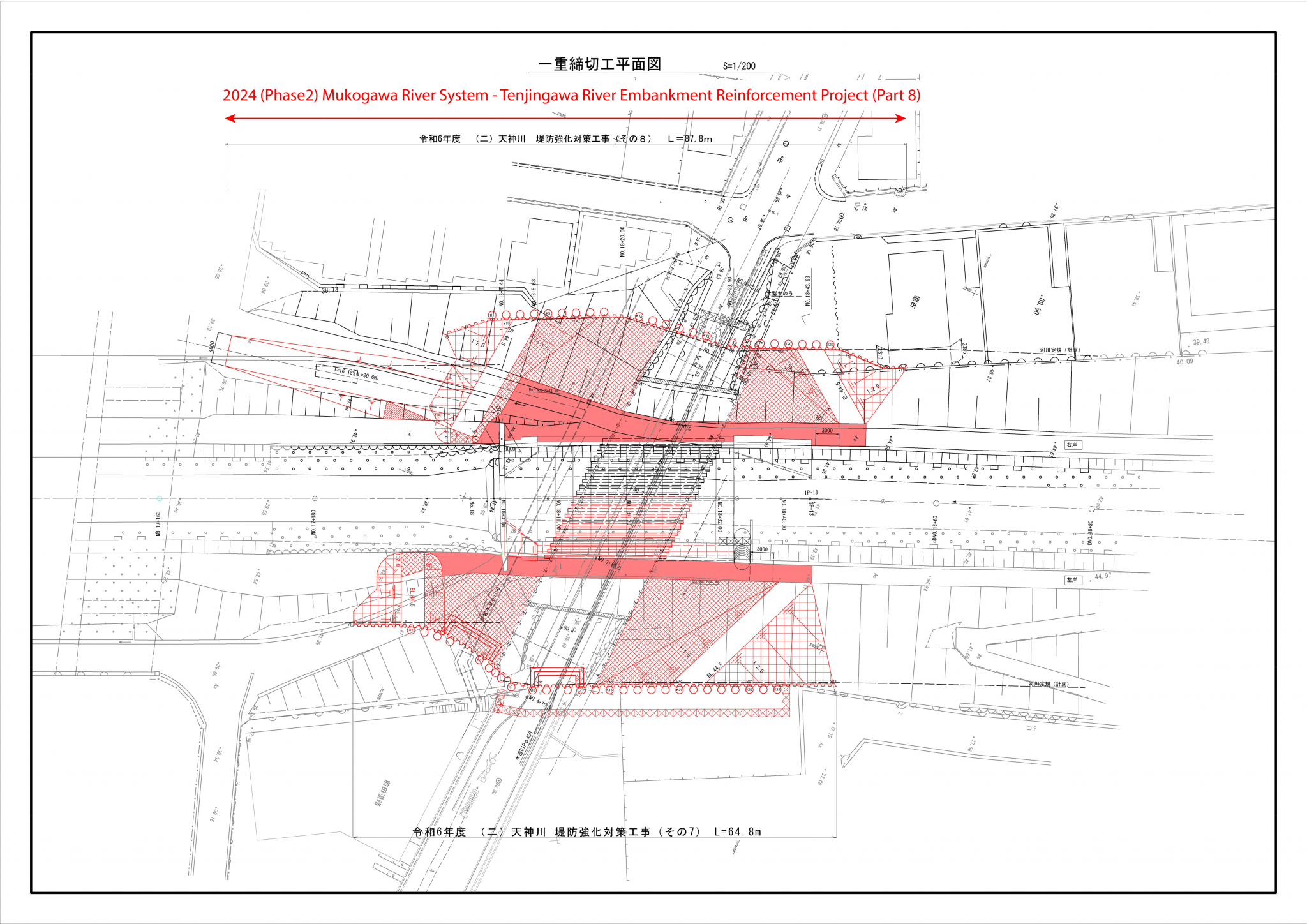

| Project Title: | 2024 (Phase 2) Mukogawa River System - Tenjingawa River Embankment Reinforcement Project (Part 8) |

| Location: | Aramaki, Itami City, Hyogo Prefecture, Japan |

| Client: | Takarazuka Public Works Office, Hanshin North District Administration Office, Hyogo Prefectural Government |

| Primary Contractor: | Shoyo Construction Co., Ltd. |

| Executing Contractor: | SATO JUKI Corporation |

| Construction Period: | December 12, 2024 - April 7, 2025 (Pile Installation) |

[Pile Specifications]

| •Hat-shaped steel sheet piles | |

| Specification: | 25H |

| Length: | 9.5 to 21.0 meters |

| Quantity: | 68 sheets |

| •Steel tubular piles | |

| Specification: | φ1000, thickness 11-24 mm |

| Length: | 19.0 to 21.5 meters |

| Quantity: | 23 piles |

Fig. 2 Cross section

What is the Combi-Gyro Method?

|

| Fig. 3 Combi-Gyro Method |

• A single press-in machine can install both Hat-shaped steel sheet piles and steel tubular piles by replacing the chuck.

*The Combi-Gyro Method is a registered trademark of GIKEN LTD. and NIPPON STEEL CORPORATION.

Q2: Typically, embankments are constructed using a double wall sheet pile cofferdam. Could you explain why the Combi-Gyro Method was selected for this project?

Mr. Aoyagi:

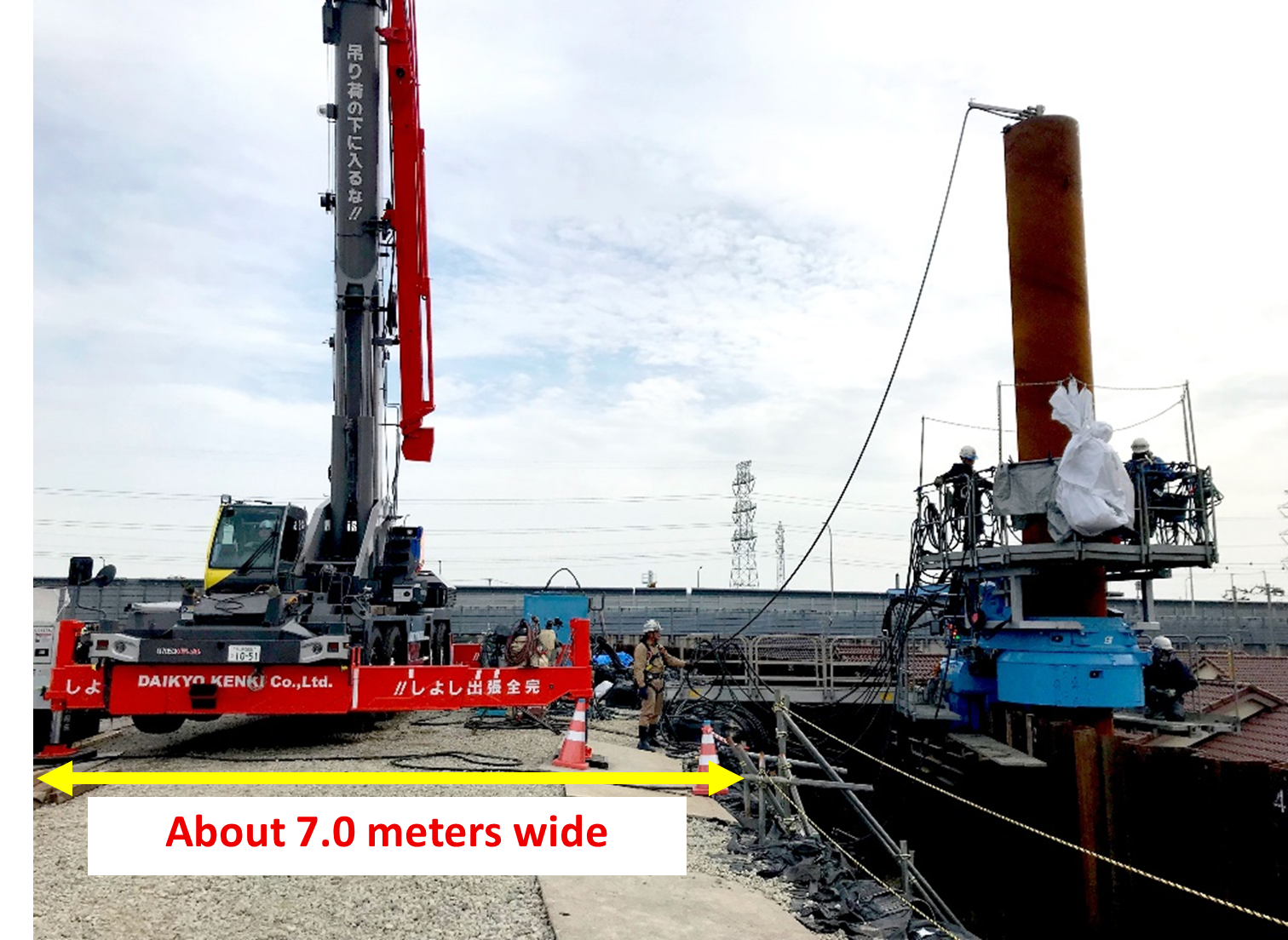

On May 8, 2023, heavy rainfall—breaking the record for the highest ever recorded in May—caused a levee breach, resulting in significant flooding. Because the site is in a densely populated residential area, installing a double wall sheet pile cofferdam would have either required fitting it within the cross-section of the existing levee or relocating neighboring houses. To keep the temporary levee as narrow as possible and address these challenges, we chose the Combi-Gyro Method. After working on-site, my impression is that the space was so tight, this method might have been the only practical option.

Q3: How is the construction progressing? Have you encountered any difficulties or challenges?

Mr. Aoyagi:

The press-in work is progressing on schedule. However, we faced significant difficulties due to the limited working space at the site. The job site was only about 7 meters wide, and the access routes for equipment were also narrow and restricted. As a result, we were unable to mobilize a large crane and had to use a 70-ton rough terrain crane instead. Since the piling work was carried out at height (approximately 6 meters), we required support lifting of the augering equipment by the crane, to ensure both safety and installation tolerances. However, because the embankment crest was 4 to 7 meters above the toe of the slope, constructing a working platform with large sandbags would have positioned the crane too far from the planned alignment. Therefore, we were unable to bring the crane close enough to safely lift the auger, which ranged in length from 18.5 to 21.0 meters.

Q4: How did you manage that issue?

Mr. Aoyagi:

We resolved the issue by splicing and detaching the auger vertically, which allowed us to use the 70‑ton crane for support lifting. However, the limited working space made the operation delicate, so we proceeded with extreme caution, especially when lowering the auger.

Q5: Among the many construction projects you have worked on, which one left the strongest impression or posed the greatest challenges?

Mr. Aoyagi:

|

| Photo 2. Mr. Aoyagi |

The most memorable project for me was during my second year with the company, when I worked on the renovation of the Tokyo Metropolitan Expressway. At that site, we were contracted to install press-in steel tubular piles using up to seven press-in machines, along with other ancillary work. I clearly remember my supervisor telling me: "Don’t limit your perspective to your own contract. From the client's point of view, your task is just one part of the entire site. Always consider the whole project." This mindset was critical, especially since multiple contractors were working in a very confined space, requiring close coordination. It was a project that truly made me realize the importance of unity and collaboration across different scopes of work.

|

| Photo 3. Mr. Iwano |

Mr. Iwano:

This current project has been the most challenging for me. With the Combi-Gyro Method, if the inclination of the Hat-shaped steel sheet piles is even slightly off, the spacing between them and the steel tubular piles will not align correctly.

This made precision control of pile installation extremely difficult. Given that the sheet piles were also long (18.5 to 21.0 meters) and needed to be installed at a high elevation, any misalignment was nearly impossible to fix once it occurred. Given my limited experience with this method, I believe the lessons I have learned here will be invaluable for future projects.

Q6: What do you think about the future of the press-in technology?

Mr. Iwano:

In recent years, digital transformation (DX) has been making progress, but I believe there are still challenges in achieving full automation and remote operation of the press-in piling machine. Since underground conditions are not visible, we sometimes encounter unexpected obstacles not shown in the site investigation reports.

Press-in work requires fine-tuning at each site, and for now, much of the process still relies on the operator’s intuition and experience. Also, since progress and quality can vary depending on operator’s skill, passing on technical skills remains a major challenge.

Mr. Aoyagi:

I also feel that press-in construction is a type of work that relies heavily on individual skill levels. To help bridge that gap, I think it is essential to continue advancing automation technologies. Compared to other types of construction machinery, press-in equipment still lags behind when it comes to remote control and automation. Given the number of accidents caused by human error, I hope we can introduce more fail-safe, foolproof systems to enhance safety on site.

Although I have been working in this industry for nine years, I noticed that young workers are fewer than senior workers at many job sites. I believe that promoting DX across the construction industry can help improve its negative images and make it more attractive to the next generation.

Comments

This interview was conducted with SATO JUKI Corporation during a site visit organized by the Japan Press-in Association (JPA). Seeing the construction site firsthand gave me a true sense of the restricted working conditions that the team described. The proximity of residential houses to the construction area was striking. I also had the chance to hear their sincere perspectives and site-specific awareness of the challenges surrounding the future of the press-in method. We hope that the industry will continue to grow as it overcomes these challenges one by one.

I would like to express my sincere appreciation to Mr. Aoyagi and Mr. Iwano for their thoughtful responses during the interviews, as well as to everyone involved for their cooperation.

We Welcome Your Contributions!

We are looking for press-in piling engineers who are willing to share their experiences and unique project case histories through interviews.

If you are interested, please contact the International Press-in Association Secretariat at: tokyo@press-in.org

| << Previous | Newsletter Top | Next >> |