Newsletter Volume 10, Issue 2 June 2025

Special Contribution

Piling works in Vietnam - Current Practice

Piling works in Vietnam - Current Practice

Phung Duc Long

President of Vietnam Society for Soil Mechanics & Geotechnical Engineering (VSSMGE)

1. Introduction

Pile foundations are necessary for cases, where the subsoil near the ground surface has low load-bearing capacity or where the soil conditions are heterogeneous. In Vietnam, pile foundations have been commonly used for heavy structures, such as high-rise buildings. The load from superstructures is transferred to the firm layers by piles or diaphragm walls.The settlement of the pile foundations is normally small. The conventional pile foundation is the most common solution for high-rise buildings worldwide, especially in the United States of America, Southeast Asia, and Vietnam. Foundations are predominantly rested on large-diameter bored piles, barrettes, or diaphragm walls, which are in many cases driven as deep as 80-100 m into the ground to reach load-bearing layers.

Pile foundations are common in Vietnam, especially in Hanoi and Ho Chi Minh City (HCMC). In the big cities in Vietnam, the soil conditions are generally unfavorable for large projects. Driven piles and jacked-in piles are often used for projects with low bearing capacity needs. High-rise buildings normally rested on long and large bored or barrette piles with the tip penetrating the dense sand layer or gravel. This paper presents the current practice of all piling works used in Vietnam.

2. Pile design in relation to geological conditions

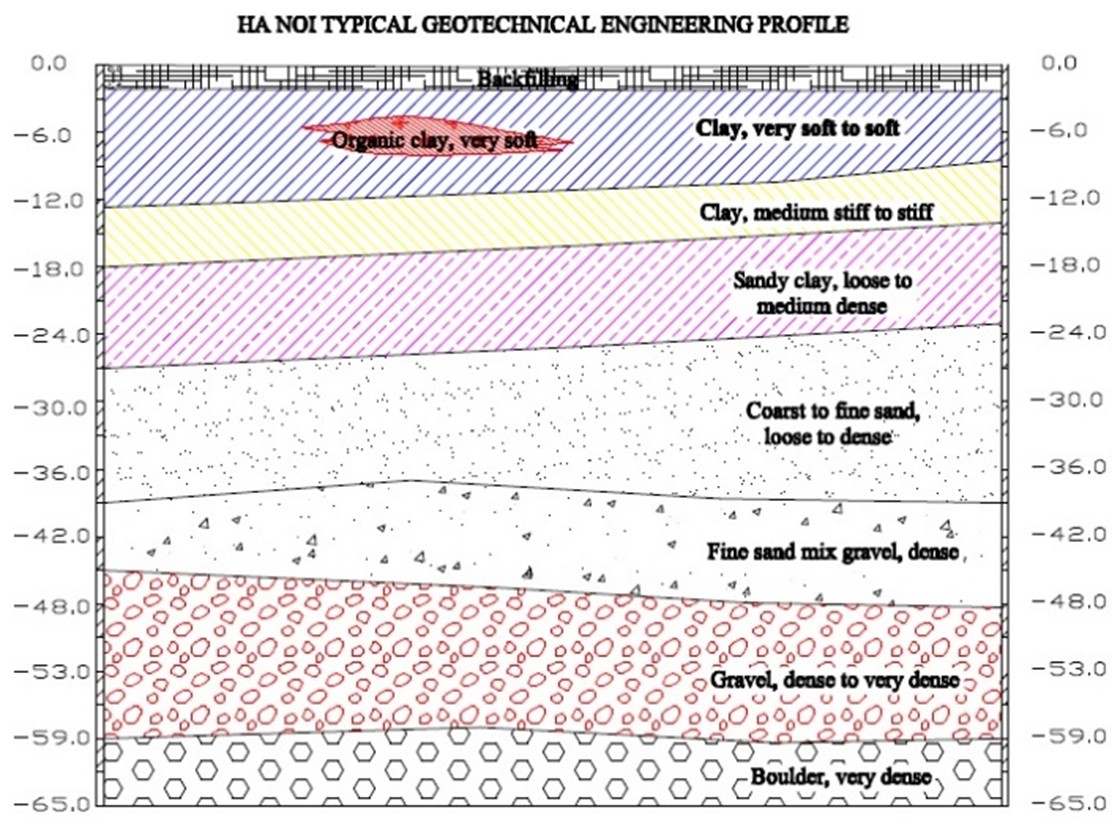

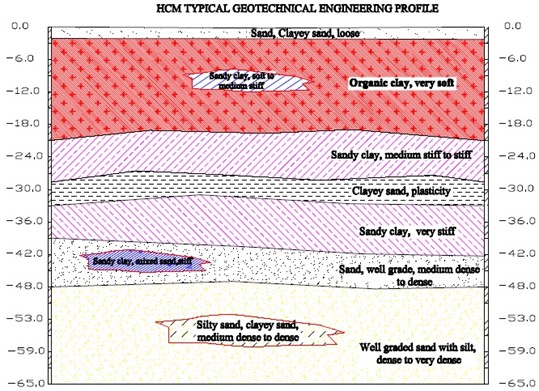

Soil conditions are very diverse in Vietnam. In the Hanoi area, soil layers were formed in the late Pleistocene and Holocene, where the firm layer is a very dense gravel layer, and can be found at a depth of around 45-60 m. The above soil layers are often fine-dense sand, clayey sand, soft to medium-stiff clay, etc. Whereas, in Ho Chi Minh City (HCMC) a thick layer of marine mud or organic soil can be commonly encountered. The firm layer can be found around 50m under the ground surface. Two typical geological engineering profiles of Hanoi and HCMC areas are shown in Figs 1 and 2.Fig. 2. Typical geological engineering profile in Ho Chi Minh City area

3. Design principles

Piling is both an art and a science. The art lies in selecting the most suitable type of pile and method of installation for the ground conditions and the form of the loading. Science enables the engineer to predict the behaviour of the piles once they are in the ground and subject to loading. This behaviour is influenced profoundly by the method used to install the piles and it may not be predicted solely from the physical properties of the pile and of the undisturbed soil. Knowledge of the available types of piling and methods of constructing piled foundations is essential for a thorough understanding of the science of their behaviour.3.1. Analytical methods

Two prevailing design codes applied for the pile design are TCXD205-98 and TCVN10304-2014, the latter one is now more legally common for projects in Vietnam. These actually can be used in parallel since the TCVN10304-2014 does not state that it is issued to replace the TCXD205-98. The design principles are fundamentally similar even though TCVN10304-2014 basically follows Russian codes (SNiP) and pile bearing capacity of a pile mobilizes from shaft resistance and pile tip bearing, as shown in Eq. (1):

Qa = (Qp + Qs - NF)/ FS – W (1)

where,

Qa = the allowable vertical bearing capacity of pile;

Qp = qp*Ap, pile tip bearing capacity; qp = unit bearing pressure capacity of pile tip; Ap = cross-sectional area of the pile;

Qs = (Σfsi)*As: pile shaft resistance; fsi= unit skin resistance along the pile shaft at the i-th soil layer; and As = lateral area of the pile;

NF = negative skin friction developing along pile length within soft soil stratum;

W = weight of pile;

FS = safety factor.

where,

Qa = the allowable vertical bearing capacity of pile;

Qp = qp*Ap, pile tip bearing capacity; qp = unit bearing pressure capacity of pile tip; Ap = cross-sectional area of the pile;

Qs = (Σfsi)*As: pile shaft resistance; fsi= unit skin resistance along the pile shaft at the i-th soil layer; and As = lateral area of the pile;

NF = negative skin friction developing along pile length within soft soil stratum;

W = weight of pile;

FS = safety factor.

The allowable loading capacity of the pile is chosen upon criteria related to (i) failure of surrounding soil; (ii) pile material strength and (iii) allowable settlement of pile foundation, whatever comes earlier throughout the evaluation process. The (i) and (iii) criteria are normally set for the working condition while the other one is almost considered in the case of driving a pre-cast pile. Subject to the available data, from laboratory tests or field tests, the loading capacity estimation of a pile can be grouped into the following cases based on (a) physical properties of the ground, (b) strength properties of the ground, and (c) field test results.

3.2. Numerical methods

Finite Element Modelling (FEM) analysis is commonly used in pile foundation design in Vietnam. In the detailed design phase, static loading tests on a single pile must be performed to verify the predicted value. These tests are expensive and difficult to be carried out. FEM cannot replace the loading tests on single piles, yet could be a reliable tool for simulating the tests, and can therefore reduce the number of tests and/or predict more accurately the pile capacity in similar conditions. FEM has recently been used by the author, for modelling the single pile loading tests, both the traditional Maintained Load Test (MLT), Phung (2023), and the bi-directional pile test, or the so-called Osterberg cell test, an alternative method to the traditional static loading tests for large piles with a high working load Phung et al. (2016). The following examples show how FEM is used in Vietnam. They are not a verification or evaluation of a case study. That's why the important information as the soil profile; pile properties and other numerical parameters are not presented in this paper. Such information can be found in the above-mentioned references.

3.2.1. FEM simulation of MLT load tests

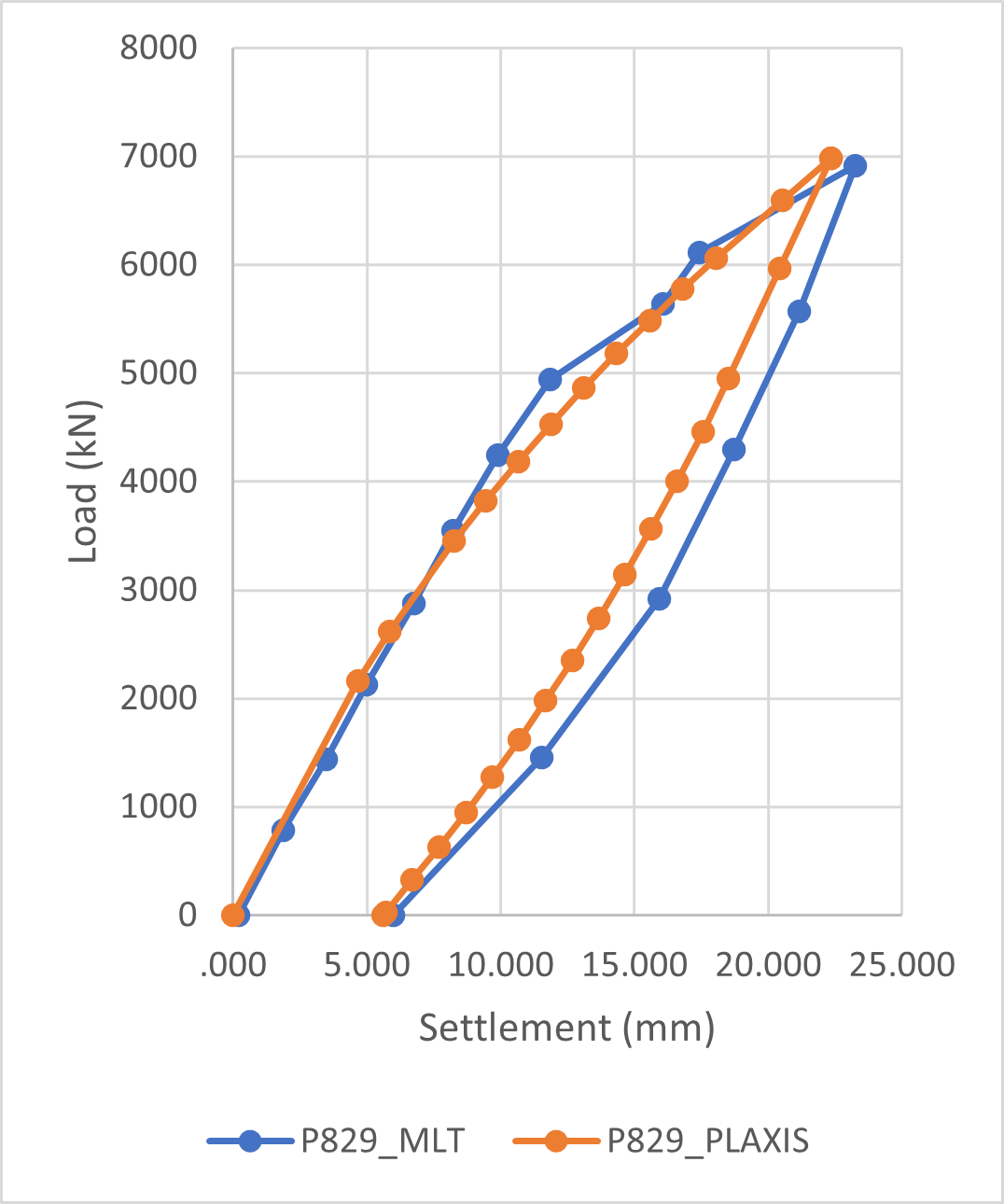

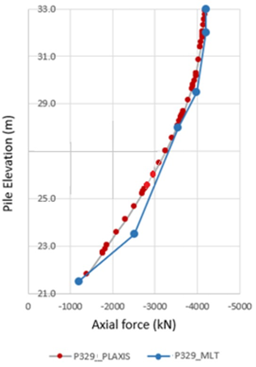

The PLAXIS software was used for modelling the traditional loading tests. The FEM model can be either PLAXIS 2D axisymmetric or PLAXIS 3D with embedded beam elements. Through the study, the author found that the axially symmetrical PLAXIS 2D is simpler and more efficient.

Parameter studies were performed to model a test to get the best fit for both the load vs settlement curve and the distribution of axial pile load vs depth, see Figs 3 and 4. From the model, best-fit soil parameters can be chosen, and further used for the detailed design of the piled foundation.

3.2.2. FEM simulation of bi-directional load tests

Under the high working loads and complicated site conditions, the conventional static load test is impractical for large-diameter bored piles with different geometry and types, in inhomogeneous geotechnical profiles. The bi-directional test, or so-called Osterberg cell (O-cell) testing method, is recently used for large-bored piles in Vietnam.

.png)

Fig. 5. Comparison of results from bi-directional test and FEM analysis using PLAXIS 2D axisymmetric model.

Phung et al. (2016) used FEM for simulating a multi-level bidirectional test of a 2.5 m-diameter, 80 m-long bored pile at the Cao Lanh cable-stayed bridge in the Mekong Delta, Vietnam. The FEM analysis using PLAXIS 2D is then compared with the monitored data. The comparison is shown in Fig. 5, and indicates generally a good agreement between the monitored and FEM results.

Many pile installation methods are used in Vietnam. Depending on the soil condition, type of pile, etc. different pile installation methods will be selected, Phung et al. (2018).

4.1. Driven piles

For not very heavy structures, the precast concrete piles are commonly used. Driven piles are useful for soft to stiff soil conditions where the firm layers can be found at about 25-35m, and without obstacles. Pre-fabricated concrete piles with a cross-section of 250 x 250mm to 350 x 350mm, and spun piles with various diameters of 300, 400, 500, and 600 are common in Vietnam. Driven steel piles are not very common. Several installation methods for these piles can be listed below. Piles are driven by diesel or hydraulic hammers (Fig. 6). Some typical hammers in Vietnam are Kobe K25, 2.5 tons, Kobe D35, 3.5 tons (Japanese), and Delmag D46, 4.6 tons, and Delmag D62, 6.2 tons (Germany).

4.2. Pile jacked-in by hydraulic pressing machine

Jack-in pile is pressed in soil using hydraulic jacks. This is one of the non-vibrating pilling methods. It can be applied for piles with a diameter of up to 600 mm. Fig. 7 shows the pictures of the pressing machine.

Fig. 7. Pile installation by pressing machine

4.3. Bored piles and D-wall (barrette) construction

Bored piles are commonly used in Vietnam with a diameter varying from 800 to 2500, or even 3500 mm. The length of piles can reach 60-70m. Bachy Soletanche has installed piles with a length of 80m at the Lancaster Lincoln project in Ho Chi Minh City. For heavy high-rise buildings, barrette piles are often used. The common types are 0.6m x 2.8m, 0.8m x 2.8m, 1.0m x 2.8m, 1.2m x 2.8m, and 1.5m x 2.8m. The deepest barrette piles are recorded at Landmark 81 Tower in Ho Chi Minh City, with a length of 90m. The tower is currently the tallest building in Vietnam with a height of 461 m and a floor area of 240,000 m2. A total of 143 shaft-grouted barrettes and plain barrettes 1.0m x 2.8m and 1.2m x 2.8m were used for the project. The piles were installed by Bachy Soletanche, Fig. 9.

Fig. 8. Installation of bored piles at different sites

Fig. 9. Landmark 81 Tower in Ho Chi Minh City and the installation of barrette piles

Fig. 9. Landmark 81 Tower in Ho Chi Minh City and the installation of barrette piles

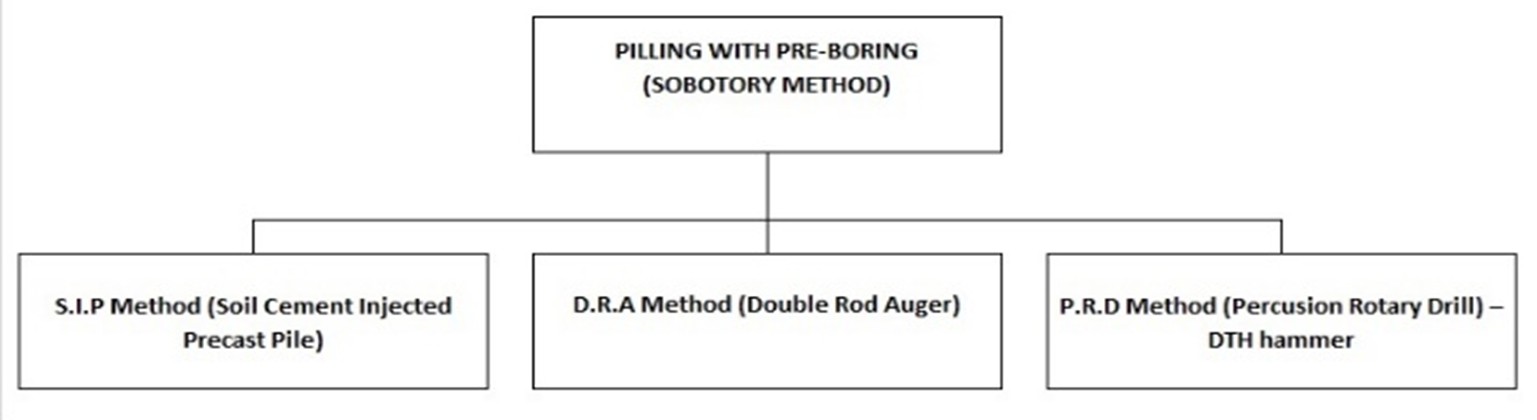

4.4. Prebored and precast piles

A prebored and precast pile is installed by boring a hole in the ground and then placing the precast pretensioned spun high strength concrete (PHC) or steel pile in the borehole with injecting cement around the pile (Fig. 10). The preboring process induces significantly less noise and vibration during construction compared to driven piles and it is more cost-effective compared to drilled shafts. Different methods of prebored and precast piles were applied in Vietnam in the 2010s. These methods bring together the advantages of traditional pile construction technologies such as bored piles (replacement), PHC piles (prefabricated piles), and CDM piles (combination). In the project of Vinh Tan 4 (Binh Thuan), the technology has been highly appreciated for quality, productivity, and low cost (20-30% reduction compared to bored piles). These methods have big advantages in complex geology which includes rock weather. The technology not only solves the problem of noise and vibration in comparison with the conventional pile-driving method, it is also easy for heavy piles to reach the designed depth in hard rock. It is therefore suitable not only for industrial construction but also for civil construction and traffic.

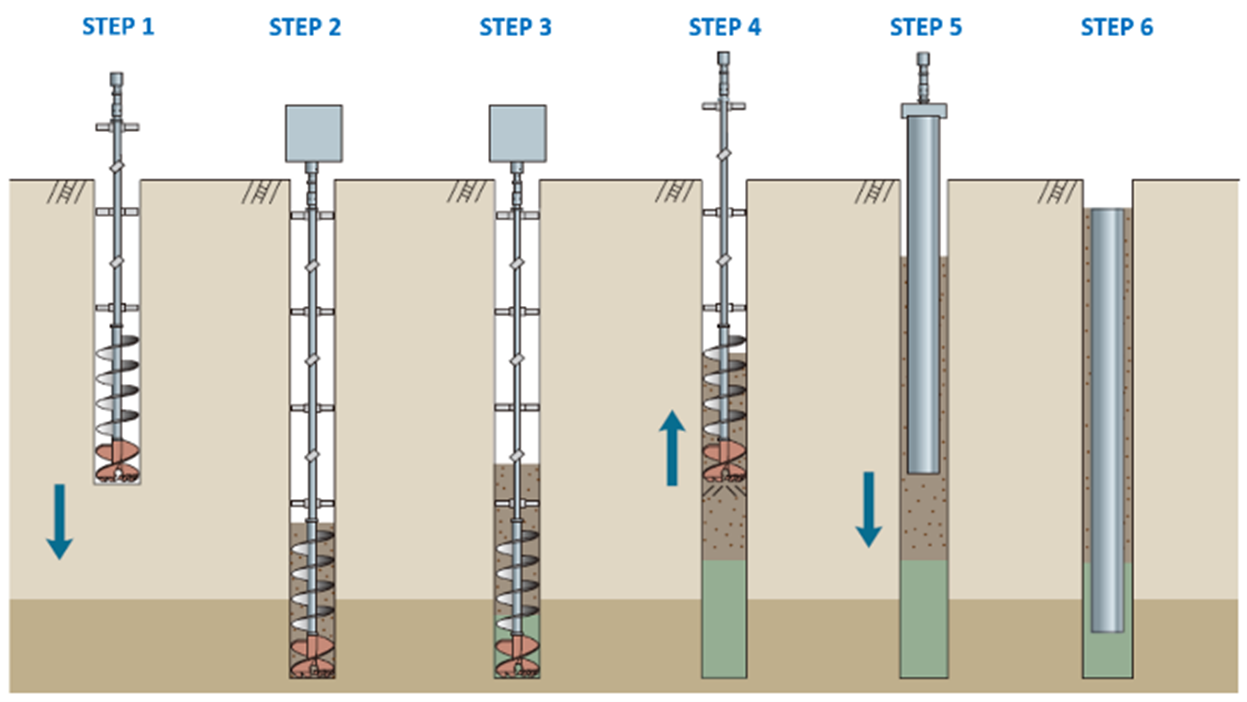

4.4.1. S.I.P Method (Soil Cement Injected Precast Pile)

The installation procedure is as follows, see also Fig. 11:

• Step 1: Drilling and mixing soil with water;

• Step 2: 1st mixing the grouted shaft with soil.;

• Step 3: Mixing the grouted base with soil;

• Step 4: 2nd mixing the grouted shaft with soil;

• Step 5: Insert pile to the design depth;

• Step 6: Light hammering and site cleaning

4.4.2. D.R.A method (Double Rod Auger)

This method involves pre-boring with the diameter of the borehole larger than the diameter of the pile. Using this method, civil complaints due to noise and vibration can be minimized. A high bearing capacity can be secured by observing removed earth and sand or rock pieces by the naked eye and then easily confirming and deciding the bearing layers. This method consists of the following features:

• Low-noise and low-vibration;

• Rapid boring through soft layers, as well as sand, gravel, and the bearing layer by using a rod auger;

• Temporary casing can prevent the collapsing phenomena;

• Excavated soil can be easily taken out;

• The pile shoe can be put into a rock layer with high bearing capacity;

• It is possible to confirm the bearing layers as the removed soil can be checked;

• Ensuring the design depth;

• Suitable for any complicated geological condition.

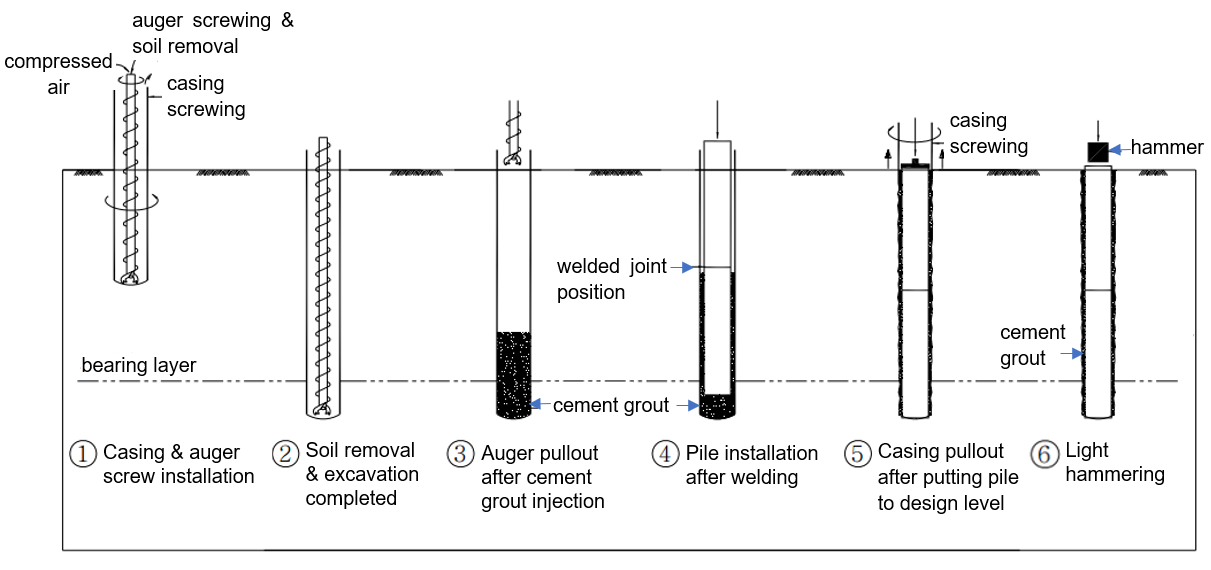

4.4.3. P.R.D method (Percussion Rotary Drill) – DTH hammer

The installation procedure is as follows, see also Fig.13,

• Drill a borehole;

• Pumping mortar into the borehole;

• Put the pile into the borehole filled with mortar;

• Use hydraulic hammer to freely fall at the pile head;

• Further filling the borehole with more mortar.

|

|

|

|

| (a, b) Drilling and pumping mortar into boreholes | c) Inserting piles in mortar | d) Driving piles by hammer | |

Fig. 13. P.R.D Method – Construction procedure

5. Conclusions

Pile foundations are common in Vietnam, especially in Hanoi and Ho Chi Minh City (HCMC). The soil conditions are varied very much in Vietnam. In the big cities in Vietnam, the soil conditions are generally unfavorable for big projects. That is why many pile installation methods are developed in Vietnam. Therefore, the regulations and standards for pilling both in the design and construction works in Vietnam need to be improved and unified.

REFERENCES

Phung Duc Long, et al., 2016. Finite element modelling of a bi-directional pile test. Proc. of Int. Conf. Geotec Hanoi 2016 Geotechnical for Sustainable Infrastructure Development (Phung Edt.), pp 47-51, November, Hanoi.

Phung Duc Long, et al., 2018. Current practice of pilling works in Vietnam. IPA Seminar on Press-in Technology in Vietnam, Hanoi, December.

Phung Duc Long, 2023. FEM simulation of single pile load tests. Proc. of Int. Conf. Geotec Hanoi 2023 Geotechnical for Sustainable Infrastructure Development (Phung Edt.), December, Hanoi.

| << Previous | Newsletter Top | Next >> |