Newsletter Volume 10, Issue 2 June 2025

Facing a Society with a Declining Population

- Challenges and Opportunities for the Construction Industry -

Ritsumeikan University

Tetsuo Yoshimoto

Professor, College of Business Administration

Ritsumeikan University

1 Issues Facing the Construction Industry in Japan

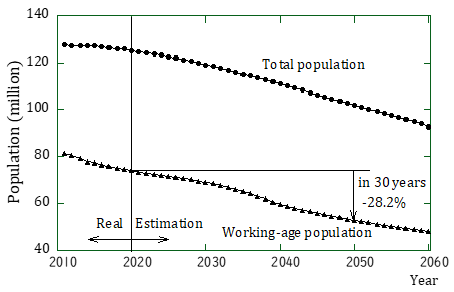

Population projections are extremely important input when considering the future of Japan. Fig. 1 shows the population projection for Japan [1]. In 2020, the total population of Japan was estimated to be 125,325,000, of which 74,058,000 were between 15 and 64 years of age, known as the working-age population. According to this projection, both the total population and the working‑age population will continue to decline and, by 2050, less than 30 years from now, the working-age population will have dropped to 52,750,000. If this scenario is realized, Japan will have to support its society with only about 70% of its current working-age population.

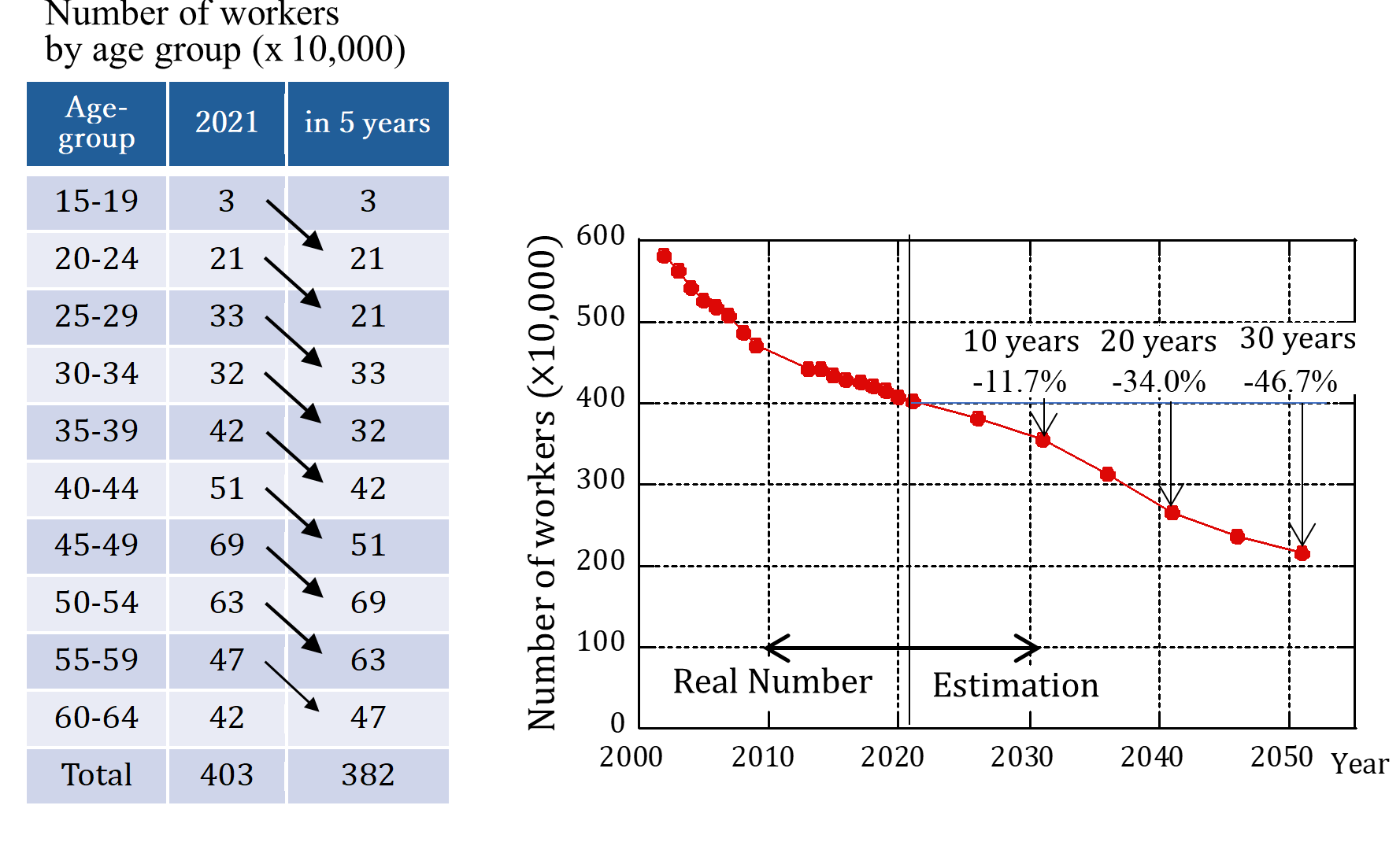

The decline in the working-age population, shown in Fig. 1, is an issue affecting all industries. However, the situation appears even more severe when we focus specifically on the construction industry. Fig. 2 shows the projected number of workers in the construction industry every five years, from 2000 to 2050. The number of workers in the construction industry is given by age group for the year 2021 published in a government statistical data source [2]. Naturally, the construction industry also includes workers who have entered the industry in the middle of their careers from other industries and those who have or will switch out of the industry to other jobs. Therefore, although these numbers are not included in the forecast, in the strict sense of the term, the approximate trend in the number of construction workers can be seen from this graph. According to this forecast, the number of workers in the construction industry will rapidly decrease and, in less than 30 years, the number of construction workers will have dropped to about half. This means that the situation of a declining working-age population is far more serious than in other industries.

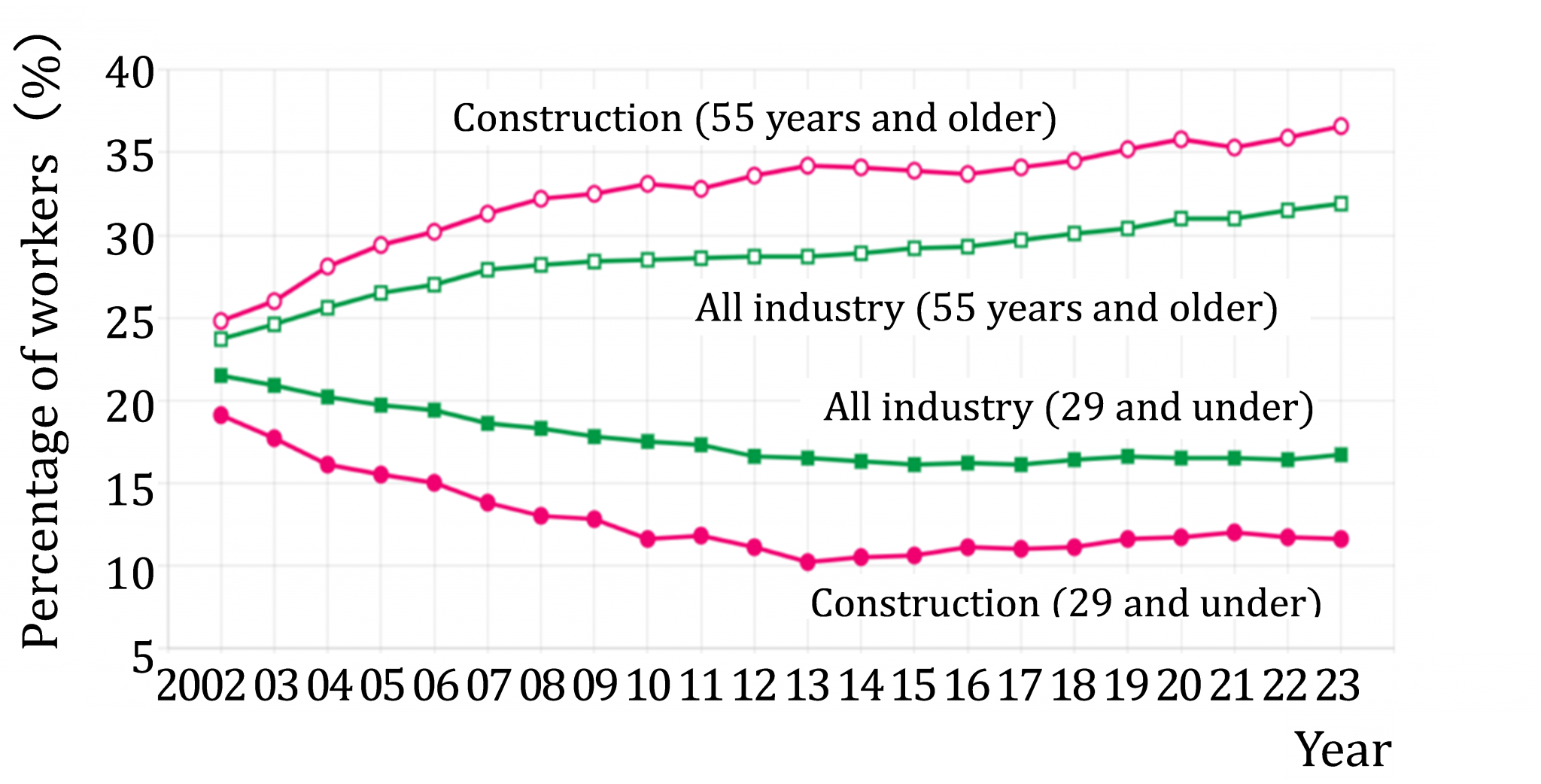

A shortage of workers is not the only problem faced by the construction industry. Fig. 3 shows the percentage of workers in each age group by industry [3].

Although the proportion of older workers, aged 55 and above, is increasing and the proportion of younger workers, aged 29 and below, is decreasing in most all industries, the proportion of skilled workers in the construction industry is particularly high. The problem is that most of these skilled workers are older and will be retiring in the near future. In the construction industry, where many uncertain factors are encountered during work, it is necessary to respond flexibly to the highly fluctuating conditions and situations at job sites. On-site workers are usually the ones to respond to these situations, and this defines the technological capability of the construction industry. In other words, the technical skills of workers in the construction industry are varied and are accumulated differently by each individual; they depend on each worker’s knowledge and experience. From an extreme viewpoint, this means that, if the most highly skilled workers leave their jobs at retirement age, no important technology will remain in an organization such as a company. Therefore, if the technical knowledge and experience of skilled workers are not passed on smoothly to the next generation of workers, the construction industry will be unable to avoid technological decline.

2 Government Policies to Solve the Problems of the Construction Industry

There seem to be only two measures that can be taken to address the severe labor shortage in the construction industry. The first is to create a system that allows for more work to be done by fewer workers than ever before, and the second is to increase the number of people entering the construction industry. The former is to dramatically improve labor productivity and efficiency in the stagnant construction industry, while the latter is to increase the attractiveness of the construction industry and the diversity of work styles, and to transform it into an industry in which different types of workers can play active roles. Digital technology, including ICT, which has been introduced in recent years, can play an important role in both of these measures.

This paper provides examples of construction reform through the introduction of digital technology.

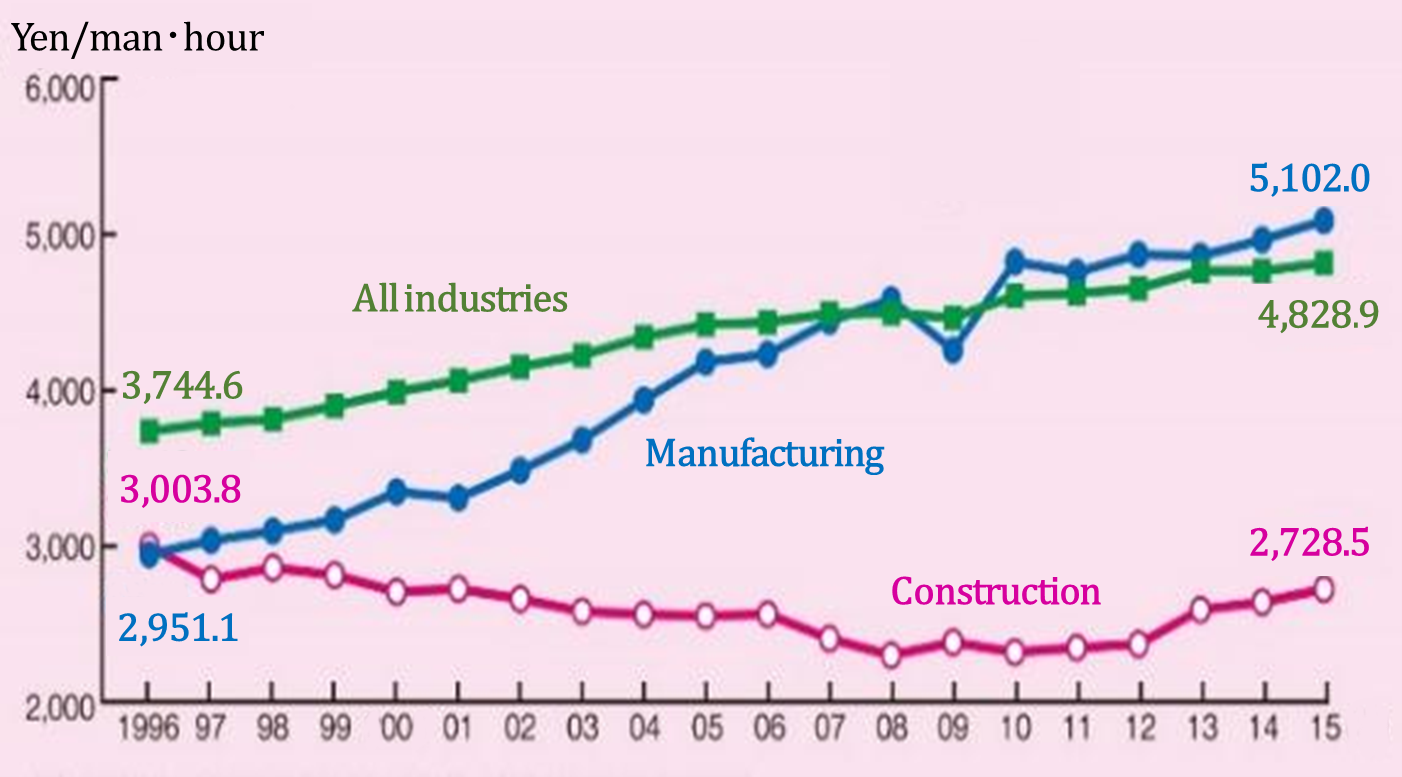

2.1 i-Construction for improvement in productivity

Fig. 4 shows changes in labor productivity by industry [4]. During the high-growth boom period in Japan, known as the “bubble economy”, the labor productivity of the construction industry remained higher than that of the general manufacturing industry. However, since the 1990s, the general manufacturing industry has made various efforts, including the introduction of new technologies, such as automation to its production lines, and has greatly improved its productivity over the past 20 or so years. The construction industry, on the other hand, has fallen into a situation where productivity has declined rather than improved due to a lack of recognition of the need to increase productivity from a slump in production capacity as construction investments have continued to decline year after year [4].

Based on the above situation, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) launched i-Construction in 2016, the aim of which is to transform the construction industry into an industry symbolized by high levels of “salary,” “vacation,” and “hope” through significant improvements in productivity. This i-Construction is based on three tactics, namely, the active use of ICT, which has lagged behind the general manufacturing industry; the standardization of criteria to improve inefficiencies caused by single-product on-site production and utilization of standardized precast members; and the balancing of orders throughout the year, as they are notably uneven at different times of the year [5]. Among these measures, there are high expectations for the improvement of productivity through the active use of ICT.

2.2 i-Construction began with earthworks

i-Construction was firstly focused on earthworks, where productivity had been sluggish compared to tunneling and other types of construction, to promote the full use of ICT and improve productivity. Earthworks is a general term for the construction of structures, such as roads and river embankments, that employ soil.

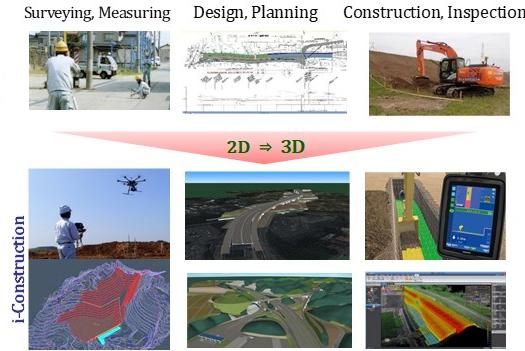

With the introduction of ICT to earthworks, it has been envisioned that drones would be used to conduct the three dimensions (3D) surveying of a site from the air at the survey stage, and that the data would then be utilized across a series of processes, including design, construction planning, construction, inspection, and maintenance (see Fig. 5).

Fig. 5. Full use of ICT in earthworks

In the past, construction work involved time-consuming manual surveying, the results of which were consolidated to two dimensions (2D) drawings. The creation of the numerous 2D drawings were based on the survey results for design and construction planning. In the construction process, temporary markers, called “finishing sticks”, were installed on site, and work was carried out based on these finishing sticks, while inspections were carried out manually over time. The i‑Construction system could be used across all phases of construction to significantly reduce labor and improve efficiency by utilizing 3D data across the board throughout all construction processes. The i-Construction approach, which started with earthworks, has since been expanded to various types of work, including pavement, dredging, and slope construction, and the technologies used in these projects have also been evolving year by year, showing a diverse range of applications.

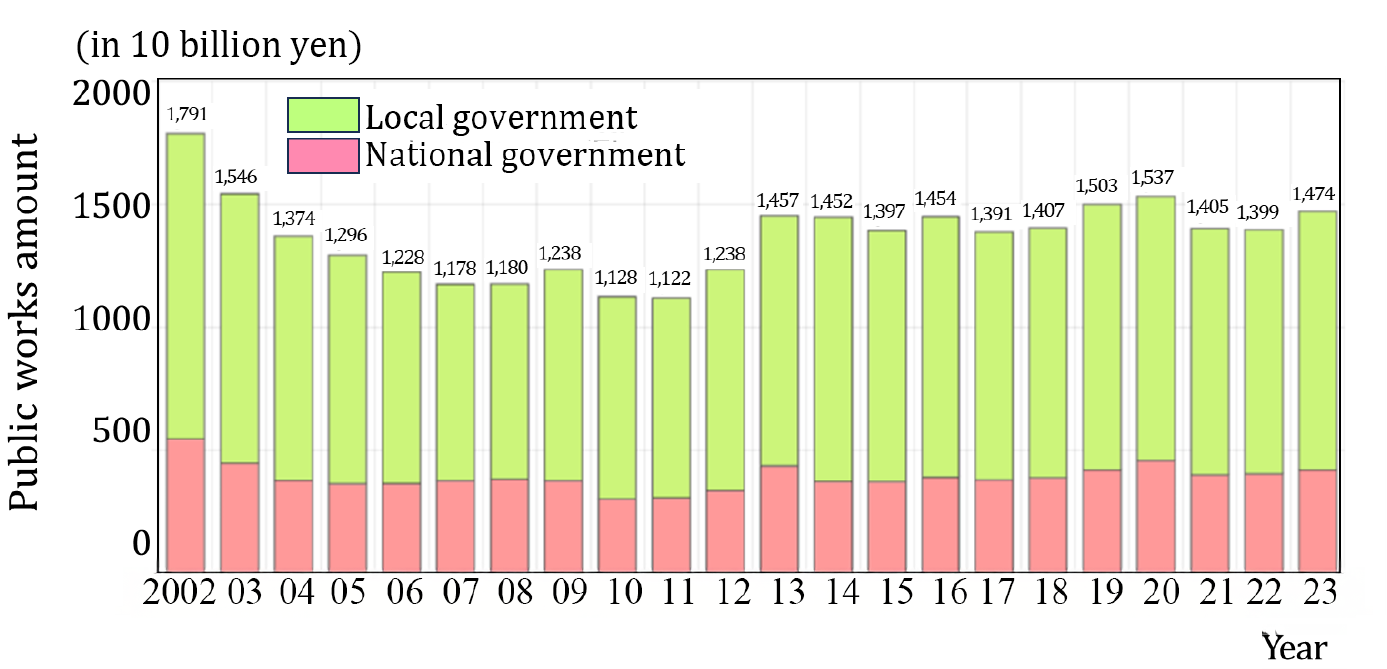

However, in small- and medium-sized construction projects, ordered by local governments, the cost of hardware and software, and the training of engineers who can use them, are barriers. And thus, for these types of projects, the introduction of i-Construction has not necessarily progressed. Fig. 6 shows the transition of public works expenditures based on the type of clients [3]. More than 70% of the public works projects related to infrastructure development are small- and medium-sized projects ordered by local governments. i-Construction will not be considered a success unless ICT is introduced in these projects. Therefore, the same methods used in the past are not sufficient for the further promotion of i-Construction, and new ways to approach the spreading of it are required.

2.3 Toward construction reform in the DX Era – Infrastructure DX-

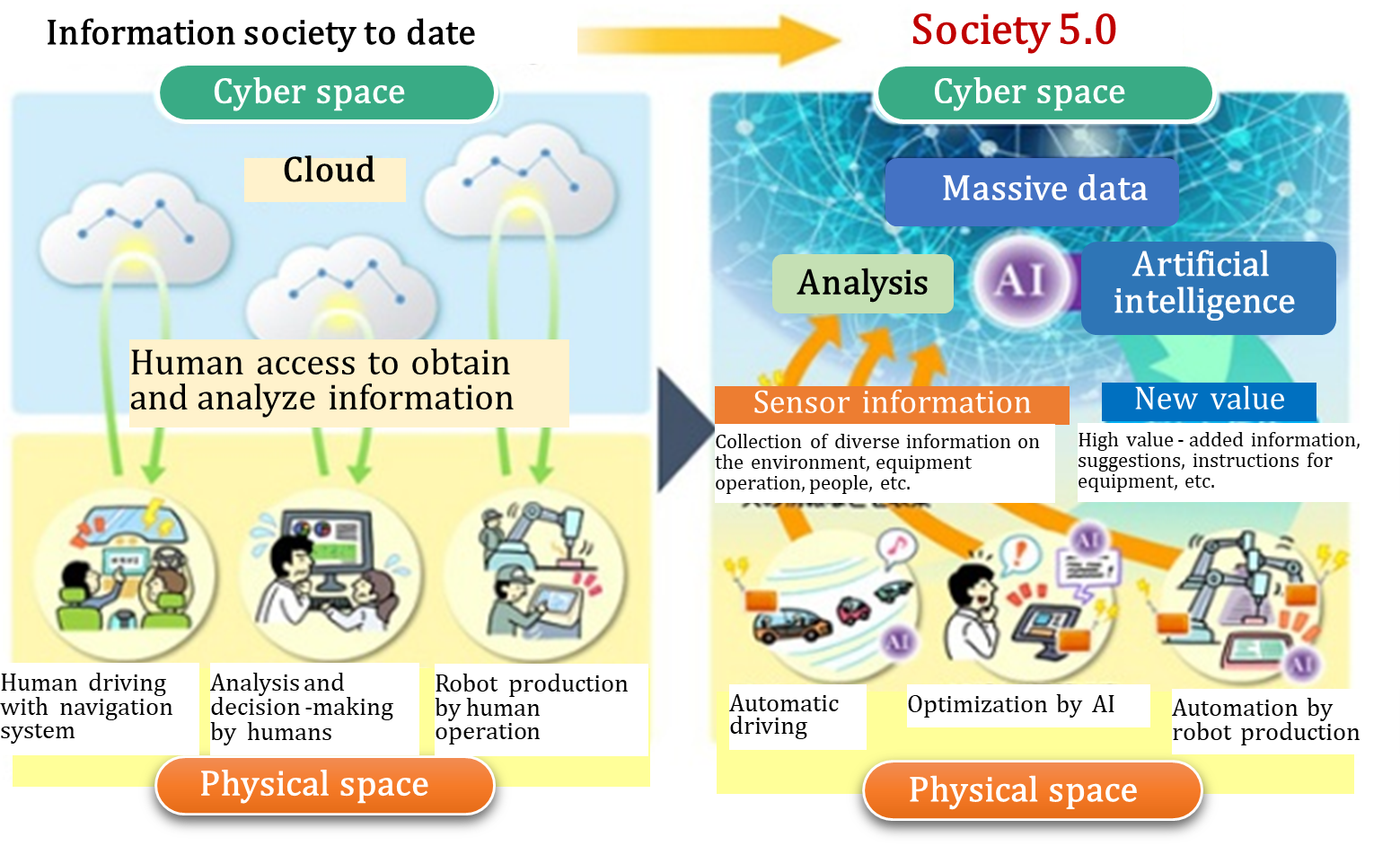

In 2016, the government proposed “Society 5.0” in the Fifth Science and Technology Basic Plan. It details the future society for which Japan should aim, namely, moving beyond hunting, agricultural, industrial, and information societies [6]. In this proposed society, a vast amount of information from the real world will be accumulated in cyberspace, analyzed by artificial intelligence (AI) as large data, and then new values based on the analysis results will be fed back to the real world, bringing about a social revolution as has never been seen before (see Fig. 8).

Digital transformation, DX, is one of the basic concepts that will play an important role in the realization of Society 5.0. DX is the concept of reforming not only business efficiency and the saving of labor, but also the business and commercial flows themselves, by fundamentally changing existing organizations, systems, procedures, and the flow of goods and information through the use of digital technologies, such as high-speed Internet, cloud services, and artificial intelligence (AI). Here, “transformation” is replaced by “X” because “X” is an abbreviation for a word that means “crossing” or “traversing”, based on the shape of the letter. Originally, “trans” meant “beyond”; and thus, “transformation” has the meaning of changing the aspect beyond the conventional framework, and the concept is expressed by the letter “X.” In other words, the goal of employing DX is not only to introduce digital technology, but also to bring about social transformation beyond the framework of the past. With this trend, digitalization will be promoted in various aspects of society; the construction field now needs to utilize digital technology more than ever before.

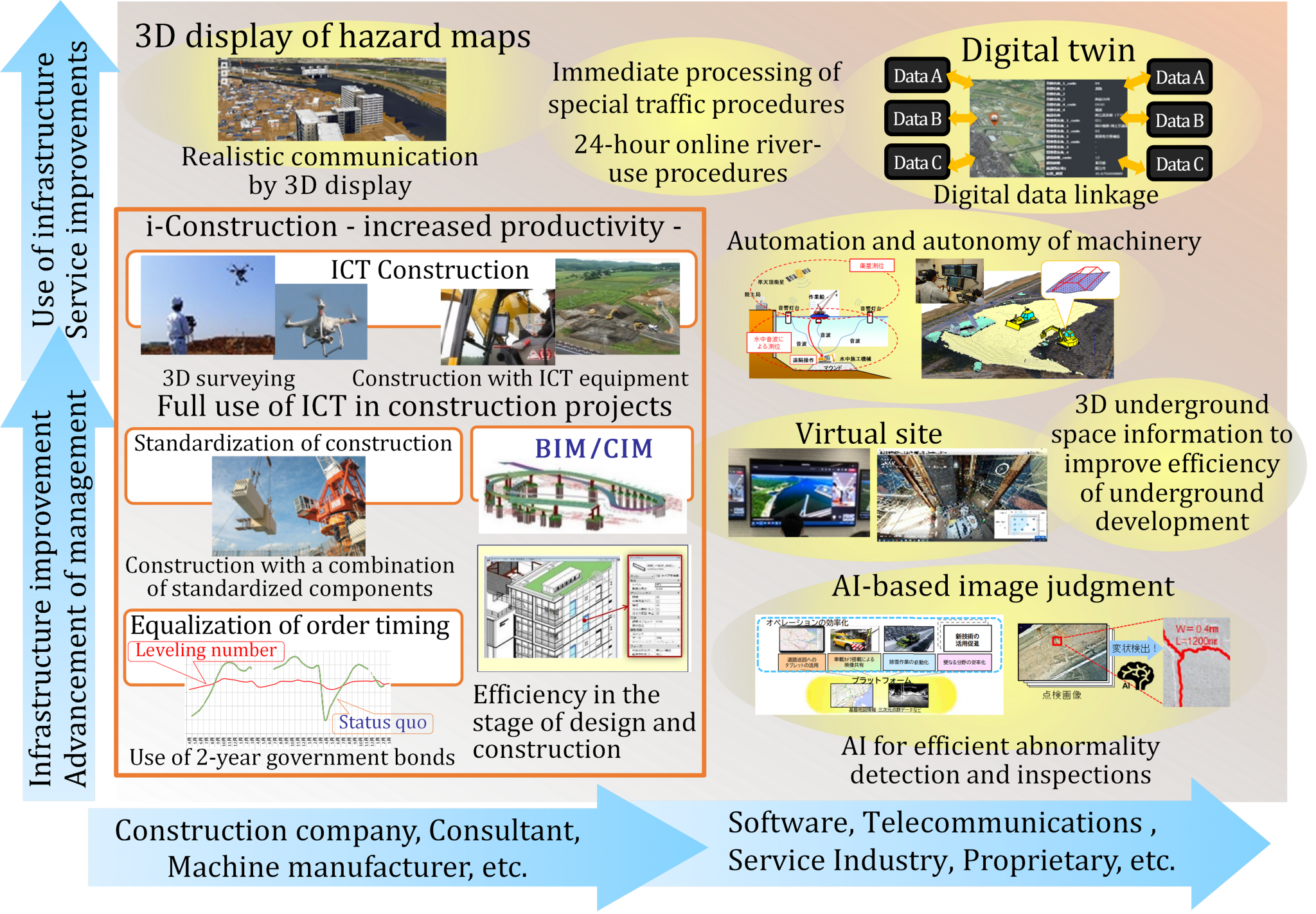

Along with this trend, in April 2022, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) proposed Infrastructure DX for the purpose of transforming construction into a more advanced industry by introducing state-of-the-art technologies, such as AI, digital twin, virtual reality (VR), and robotics, to the existing i-Construction [7]. Fig. 8 shows an image of Infrastructure DX.

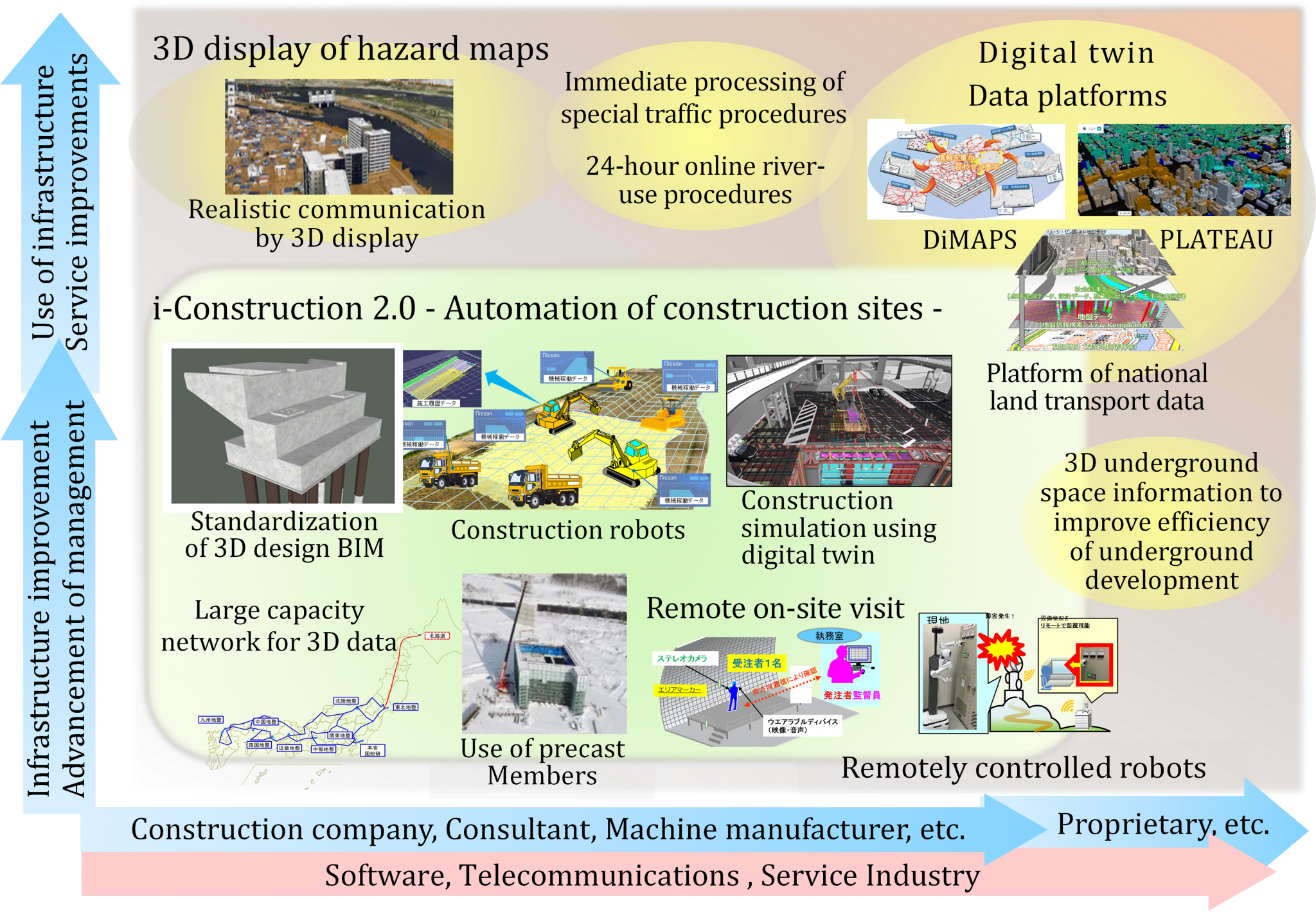

2.4 i-Construction 2.0

Furthermore, based on the significant advances in robot technology achieved in recent years, autonomous robots are now being used for construction work in the construction field. Although the various conditions related to weather, geology, construction methods, and other factors change in complex ways in construction work, requiring appropriate decisions to be made according to the uncertain situations, AI can now play a role by assisting with these decisions. In light of this change to some reliance on autonomous robots, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) proposed i-Construction 2.0 in April 2024, aiming for automation in construction work similar to that in the manufacturing industry [8]. Fig. 9 shows an image of i‑Construction 2.0.

Comparing Fig. 8 and Fig. 9, it is seen that, at the stage in Fig. 8, new technologies, such as digital twin and AI, have been added in addition to core technologies, such as ICT construction and BIM/CIM. In Fig. 9, however, these technologies have been integrated and replaced by more practical technologies. The aim of Construction 2.0 is to transform the construction industry by 2040 into one in which a fusion of these technologies has been realized and is being effectively utilized.

Fig. 9. Image of i-Construction 2.0

3 Significance of ICT Introduction

Let us review the significance of introducing ICT into the construction industry. Although there may be various other perspectives, this paper introduces the following three perspectives.

(1) Promotion of efficiency and saving of manpower in construction work

The introduction of ICT can promote efficiency, save labor, and improve productivity. In addition, the automation and autonomy of construction work when applying ICT can lead to a significant saving of manpower.

(2) Creation of opportunities for diverse human resources

ICT makes it possible for people who have never been involved in construction work to share the work. This will create a system in which construction engineers can concentrate on more specialized tasks.

(3) Reduction of excess through precise management

By utilizing ICT, it is possible to create a system to optimize construction work by eliminating excess and waste through a precise understanding of the on-site situation and flexible adjustments to the construction process.

Each of these perspectives is explained below using specific examples.

3.1 Promotion of efficiency and saving of manpower in construction work

3.1.1 Example of effective use of ICT (example of slope construction)

Daisho Co., Ltd., headquartered in Nagahama City, Shiga Prefecture, is a construction company that specializes in slope work. In the past, workers and supervisors had to climb up to the slope surface to take measurements using tape measures and other tools. To address this issue, the company established in-house technology for 3D surveying using a drone for the profile measurements (see Fig. 10). This technology has made it possible to finish in eight hours what used to take 88 hours, including data processing and measurements, without the need for workers to perform dangerous work on the slope surface. Recently, the company has been working on the development of 3D BIM/CIM technology to check the interference of ground anchors. The introduction of ICT has already begun to significantly reduce manpower and time. There are countless other examples of the saving of manpower and the improvement in efficiency that have been achieved through the introduction of ICT.

3.1.2 Automation and Robotization in Construction

The introduction of robots to the construction sector is said to be lagging behind the general manufacturing industry, where factory automation (FA) is widely used, by 20 to 30 years. This is due to the unique characteristics of the construction industry. The following are some of the reasons for this delay.

1) As the construction industry deals with natural materials, such as earth and sand, their conditions are diverse and difficult to anticipate in advance.

2) As the work environment is outdoors, there are many uncertain and variable factors related to weather, geology, etc.

3) Each work object is located in a fixed position in or on mountains, rivers, etc., and the machines used to perform the construction have to maneuver over or around the object to perform the work.

Therefore, robots used in the construction field must have the ability to make judgments in advance according to each site and circumstance, which has been a barrier to their practical application. This situation has been changing significantly, however, with the recent implementation of AI in the field. Fig. 11 shows an example.

In this construction system, an unmanned dump truck autonomously transports and unloads soil at the site, and a bulldozer moves, according to the shape of the soil, to spread it evenly to a predetermined thickness. Vibratory rollers then roll and uniformly compact the soil a predetermined number of times. The location and environment of the site changes from moment to moment, but these machines can work autonomously and in coordination with each other according to the situation. This system has been realized by the implementation of AI. Currently, the introduction of this technology is limited to large-scale construction projects, such as dams, but it is expected to be generalized for use in urban construction projects in the future.

3.2 Creation of opportunities for diverse human resources

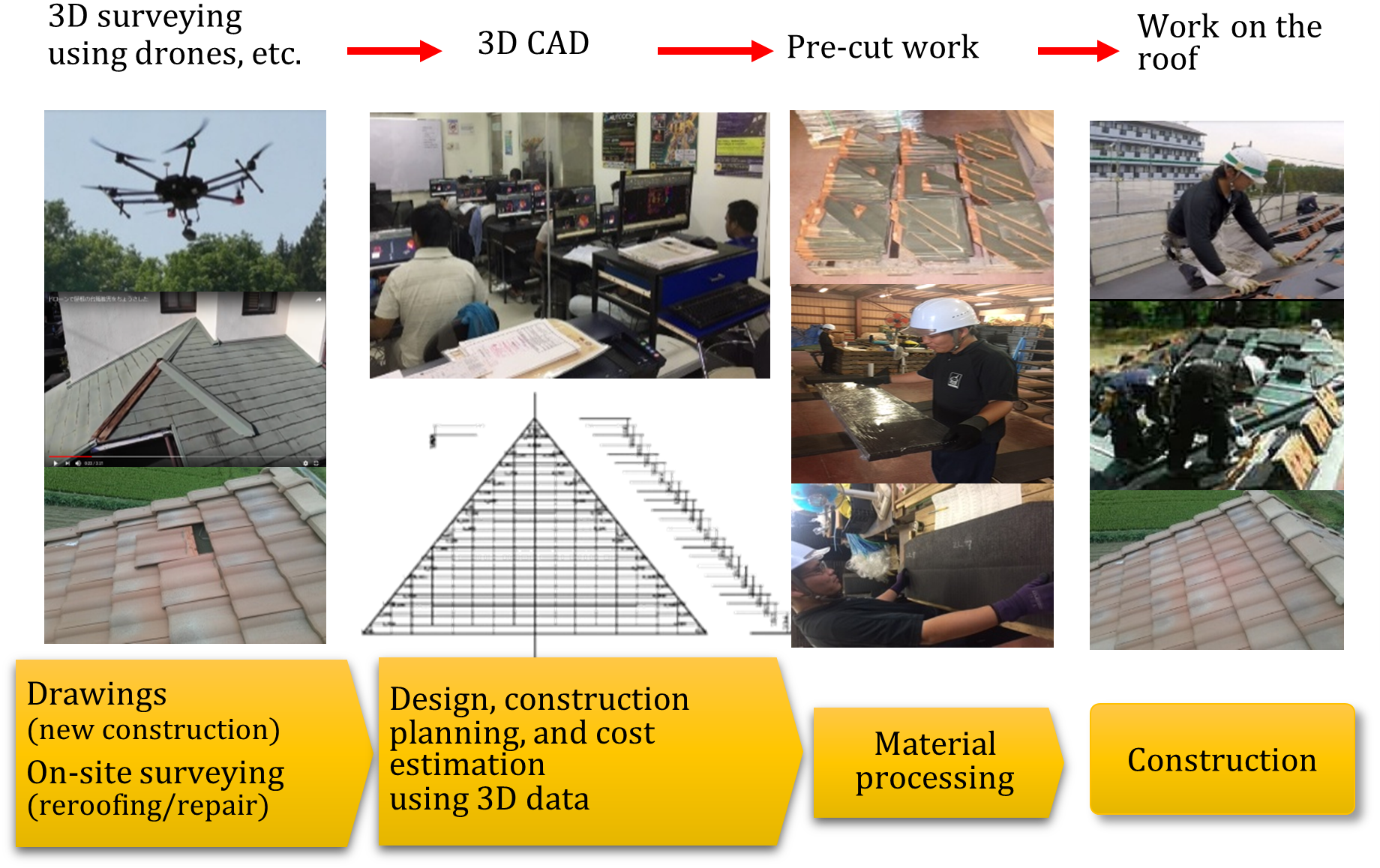

ICT makes it possible for people who have never been involved in construction work to share the work and play active roles, thereby creating a system that allows construction engineers to focus on more specialized work. Here is an example of roofing. Roofing is a type of work that has traditionally been highly dependent on craftsmen. For example, when roof tiles are replaced, craftsmen measure the dimensions and shape of the roof on it, order the tiles based on these measurements, and then lift the delivered tiles onto the roof to replace the old ones. The tiles must be cut, if necessary, to fit the dimensions and shape of the roof. These tasks are performed at high elevations on the roof, which can be extremely dangerous, making it difficult to foster successors to the occupation. For this reason, one roofing company has established a construction method that minimizes its dependence on craftsmen. Fig. 12 shows the construction process.

In this method, the dimensions and shape of the roof are surveyed in 3D from the sky using a drone and, based on the data, a simulation of the arrangement of the tiles is performed using 3D CAD. According to this data, the size and number of tiles, as well as the areas that require the partial cutting of tiles, are determined, and the tiles can then be cut in advance at the factory. Through this series of steps, the roof can be reroofed with perfectly set tiles. The only part of the process that is done by craftsmen is the final re-thatching of the roof tiles. The surveying of the dimensions and shape of the roof is performed by the drone operator, and CAD simulations are performed by CAD operators. The company has established a school for training CAD operators in the Philippines; it employs high school graduates in the Philippines to perform CAD operations. Since data is exchanged over the Internet, the presence or absence of national borders is irrelevant. In addition, the company employs people with physical disabilities to pre-cut the roof tiles in the factory. These people, who have never been involved in roofing before, take on some of the work that the craftsmen used to do, allowing the craftsmen to concentrate on the work of re-thatching the roof tiles. In this way, the introduction of ICT can improve the efficiency of the entire organization by having others take on some of the work previously done by engineers and technicians, allowing the engineers and technicians to concentrate on the work that requires higher skills or more experience.

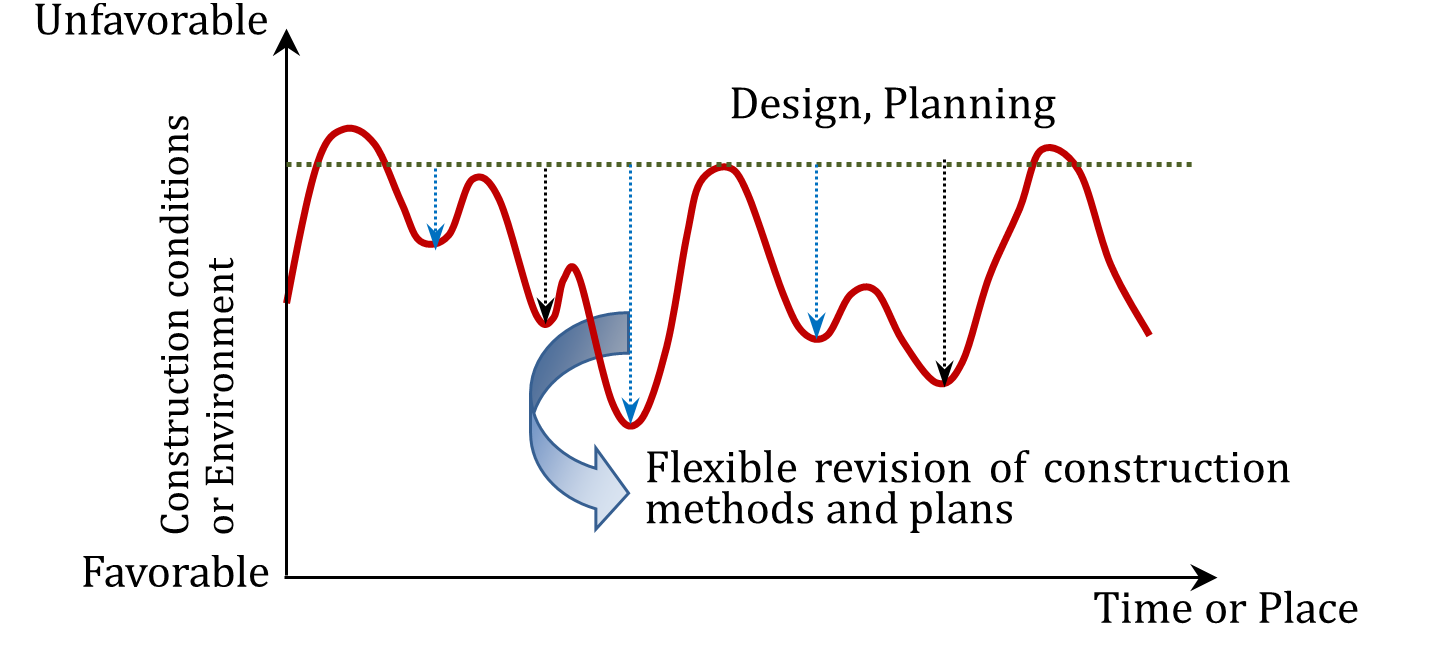

3.3 Reduction of excess through precise management

Construction is an industry with many uncertainties because it is affected by weather, geology, operator skill, and other factors. Standards and manuals for construction work are set up with margins of error to allow for the possibility that the work may need to be performed under unfavorable site conditions. The safety factor in the design is said to be for this purpose. In reality, however, site conditions are not always unfavorable. As a result, when construction is carried out according to general standards and the manuals, there are many cases where more materials and energy than necessary are utilized. In such cases, while using criteria and manuals as standards, it is possible to optimize construction by reducing the excess of materials, energy, and manpower by employing sensors and ICT to understand the gaps between the design and plan and the actual conditions, and by adjusting the construction methods accordingly. Fig. 13 shows an image of such a system.

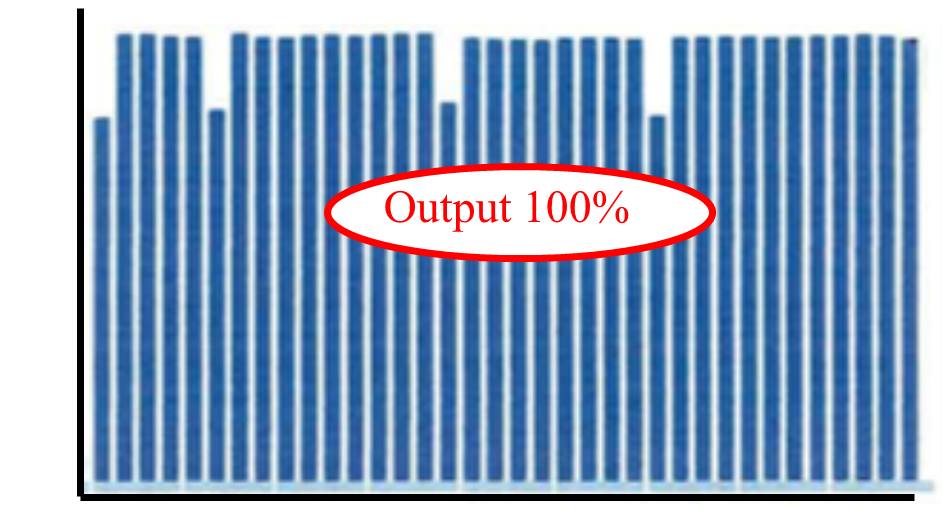

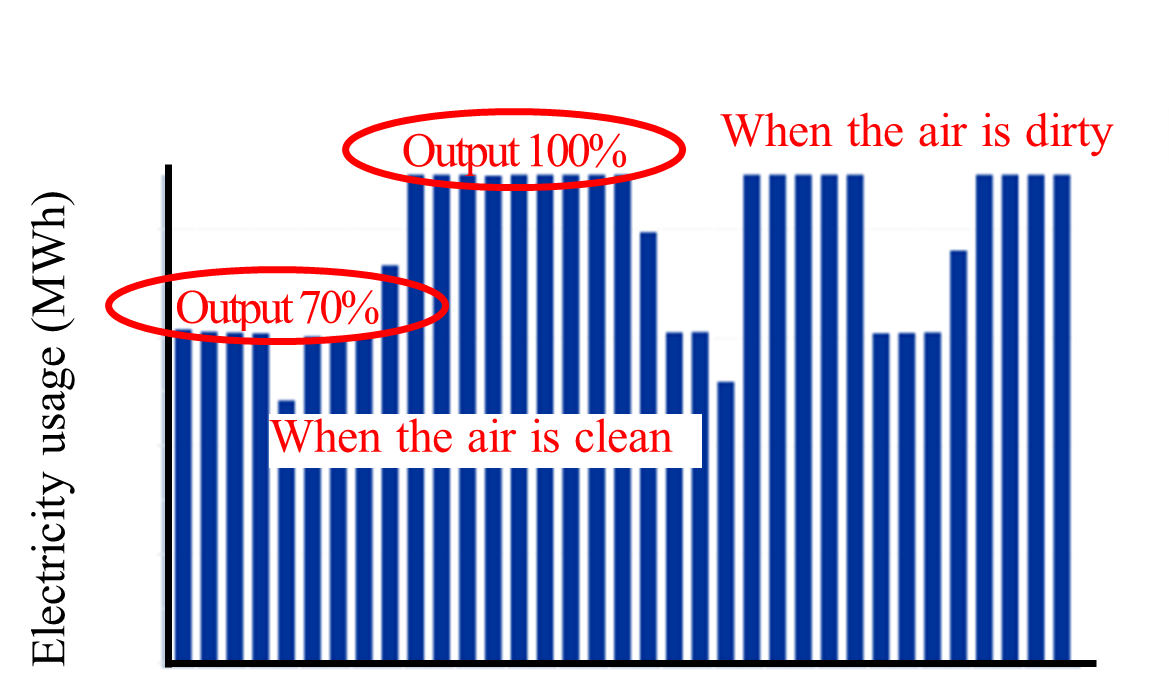

The following is an example of a mountain tunnel construction. Tunnel construction requires ventilation to maintain a normal working environment inside the tunnel. As shown in Fig. 14(a), a large blower is used to circulate air in and out of the tunnel. Usually, the capacity of the blower is designed to allow work to be performed even when the air is dirty, such as after blasting or during shotcrete work, and the blower is often operated constantly to supply air, as shown in Fig. 14(b).

However, as the degree of air pollution in a mine differs during times of blasting, shotcrete, mucking, and other operations, the output of the blower has to be adjusted, according to the work being done in the mine, after confirming the measurement results of CO2, dust, oxygen concentration, and toxic gases at the site. Fig. 14(c) gives an example of the operation of a blower at a construction site. At this site, the airflow was controlled at 100% output when the air was dirty, and at 70% output when it was less dirty, thereby significantly reducing the energy consumption of the ventilation system.

As shown in this case study, sophisticated management based on on-site information can reduce the excess and waste in the construction and optimize the construction process. This means that efficiency in the construction and a reduction of the environmental impact can be achieved at the same time. Similar cases are expected to increase in the future.

4 Conclusion

In an era of rapid change, such as the current one, it is important to consider that remaining unchanged is not a matter of “maintaining the status quo,” but rather a matter of “decline”. In the construction industry, issues such as labor shortages are becoming more serious every year. On the other hand, various technologies, especially digital technologies, have evolved significantly, making it easier to implement solutions to these issues by adopting new technologies and ideas. In this sense, the construction industry now has a great opportunity to change drastically.

There are several images of what the next generation of the construction industry could look like due to this transformation. They include the following.

- An industry in which various innovations are tried and tested from the front-line site level to the level of the overall construction system.

- An industry where everyone endeavors to reach the next level.

- An industry that appreciates the challenge of reform, even if it fails, rather than blaming the failure.

- An industry that values diversity and actively promotes collaboration among different fields.

- An industry that is full of diversity, where people of different genders, nationalities, ages, and occupations work together.

However, the above images of the construction industry in the future are not be fixed, but should change in response to the trends of the times and changes in the environment, and should welcome the creation of completely different images in the future. It is highly anticipated that many people involved in the construction industry will continue to boldly take up challenges in this ever‑changing environment and create new and different images of the construction industry in the future.

References

[1] National Institute of Population and Social Security Research: Population Projections for Japan (2017 estimates)

https://www.ipss.go.jp/pp-zenkoku/j/zenkoku2017/db_zenkoku2017/g_tables/pp29gt0101.htm

[2] Government Statistics, e-Stat (Labor Force Survey): Number of workers by industry Construction 2021.

[3] Japan Construction Industry Association: Construction Industry Handbook 2023.

[4] Japan Construction Industry Association: Construction Industry Handbook 2020.

[5] Ministry of Land, Infrastructure, Transport and Tourism: i-Construction - Production Revolution at Construction Sites, i-Construction Committee Report, April 2016.

[6] Cabinet Office: Science and Technology Policy, From Society 5.0.

https://www8.cao.go.jp/cstp/society5_0/index.html

[7] Ministry of Land, Infrastructure, Transport and Tourism: DX Action Plan for Infrastructure Sector, March 2022.

https://www.mlit.go.jp/tec/content/001474432.pdf

[8] Ministry of Land, Infrastructure, Transport and Tourism: “i-Construction 2.0” - Productivity Improvement through Automation of Construction Sites, April 16, 2024.

https://www1.mlit.go.jp/report/press/kanbo08_hh_001085.html

A brief CV of Prof. Kazuyoshi Tateyama

Kazuyoshi Tateyama is a professor at Research Organization of Science and Technology, Ritsumeikan University. After he graduated from the Department of Civil Engineering, Kyoto University in 1980, and received his master's and doctoral degrees from Kyoto University, he worked as a research associate, lecturer, and assistant professor at Kyoto University from 1985, and became a professor at Ritsumeikan University in April 2004. He has been engaged in research to improve productivity and safety by utilizing ICT in construction work, and has been working to expand the use of ICT to social initiatives. He chaired the Construction Robotics Committee of the Japan Society of Civil Engineers (JSCE) and has served as a member of numerous technical councils, including the Ministry of Land, Infrastructure, Transport and Tourism.

A brief CV of Prof. Tetsuo Yoshimoto

Tetsuo Yoshimoto is a professor at College of Business Administration, Ritsumeikan University. After he graduated from the Department of Commerce, Doshisha University in 2004. he worked as a research associate at Graduate School of Economics, Tokyo University, lecturer at Department of Commerce, and assistant professor at College of Business Administration Ritsumeikan University. He is specialized in technology management and innovation management. He is working on construction process innovations. He is a member of the Engineering Academy of Japan (EAJ), which emphasizes Transdisciplinary Research.

| << Previous | Newsletter Top | Next >> |