Newsletter Volume 10, Issue 1 March 2025

Advancements in Sustainable Construction:

The GEOTETS Method and Its Impact on CO2 Emissions Reduction

Yasuhiko Nishi

CEO of Civil Assist Co., Ltd.

The current state of sustainability in the construction sector is progressing towards achieving carbon neutrality and a circular society. Efforts to reduce the overall environmental impact of construction projects include improving energy efficiency, utilizing renewable energy, and introducing low-carbon technologies. Among these, the reuse of materials holds a particularly important position. Reusing materials significantly contributes to reducing CO2 emissions, effectively utilizing resources, and reducing waste. The manufacturing of construction materials requires a large amount of energy, resulting in substantial CO2 emissions. By reusing materials, the production of new materials can be reduced, thus lowering embodied carbon (CO2 emissions during the manufacturing of building materials). Additionally, it prevents resource depletion and enables sustainable resource use.

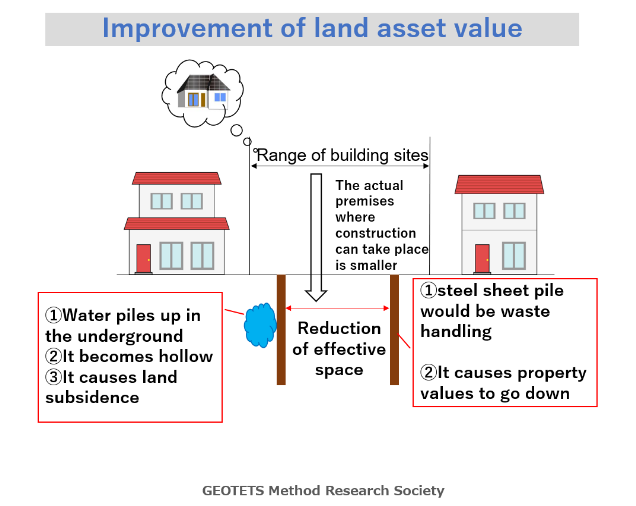

Steel sheet piles are a representative reusable material that is repeatedly used (reused) after being extracted from construction sites. This process not only provides low-cost, high-quality steel but also contributes to reducing CO2 emissions associated with the production of new steel. However, there are several challenges in reusing steel sheet piles. Particularly, when extracting steel sheet piles from the ground, voids may form in the soil, causing ground loosening. This loosening can lead to decreased ground stability, adversely affecting nearby buildings and infrastructure. This is a significant issue in urban areas and regions with dense buildings.

To overcome these challenges, appropriate technology and management are required. This article introduces the GEOTETS method developed to solve these issues. Furthermore, it examines the effects and potential of the GEOTETS method from the perspective of sustainability.

2. GEOTETS Method1)

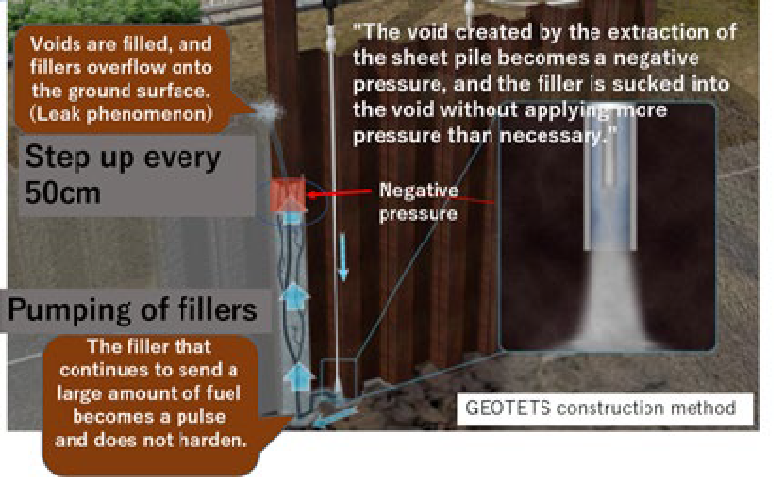

The GEOTETS method is a technique that suppresses ground subsidence around steel sheet piles during extraction, allowing for safe removal (Fig.1). By applying this method, it is possible to suppress the subsidence of the main body of buildings around the steel sheet piles and prevent quality degradation such as differential settlement. Additionally, it prevents damage to surrounding houses and public facilities due to ground subsidence, avoiding unnecessary business losses and future risks. This method has already been applied in over 900 cases (Fig.2).

In this method as shown in Fig.1, a filling pipe is first installed along the steel sheet pile, and extraction is performed in increments of 50 cm using construction machinery. Each time a void forms, filling material is injected through the filling pipe. When the steel sheet pile is lifted by 50 cm, the space occupied by the steel sheet pile becomes a void, creating a negative pressure state. Soil particles, moisture, and air around the void are drawn into this space. In this method, filling material with a higher density than water is injected at the same pressure level as the negative pressure simultaneously with the extraction, filling only the space under negative pressure quickly. This prevents unnecessary soil injection, and the space shaped like the steel sheet pile is filled with filling material, solidifying in a few minutes and forming a filling material steel sheet pile. This process is repeated until all steel sheet piles are extracted. The injected filling material gels in about one minute, filling the voids, enabling semi-permanent ground measures.

3. Reduction of CO2 Emissions

3.1 Reduction of CO2 Emissions through Reuse

By applying this method, the reuse of steel materials becomes possible. Based on the 900 cases, the total weight of reusable steel materials is estimated to be approximately 54,000 tons (assuming an average of 50 steel sheet piles of type III, L=8m per case). This results in a reduction of new steel production of the same weight, leading to a reduction of CO2 emissions associated with steel production by 74,000 tons. The application of this method has increased rapidly since 2022, and as of this year, it has already exceeded 160 cases, contributing to an annual CO2 reduction of 13,000 tons.

3.2 Secondary Reduction of CO2 Emissions

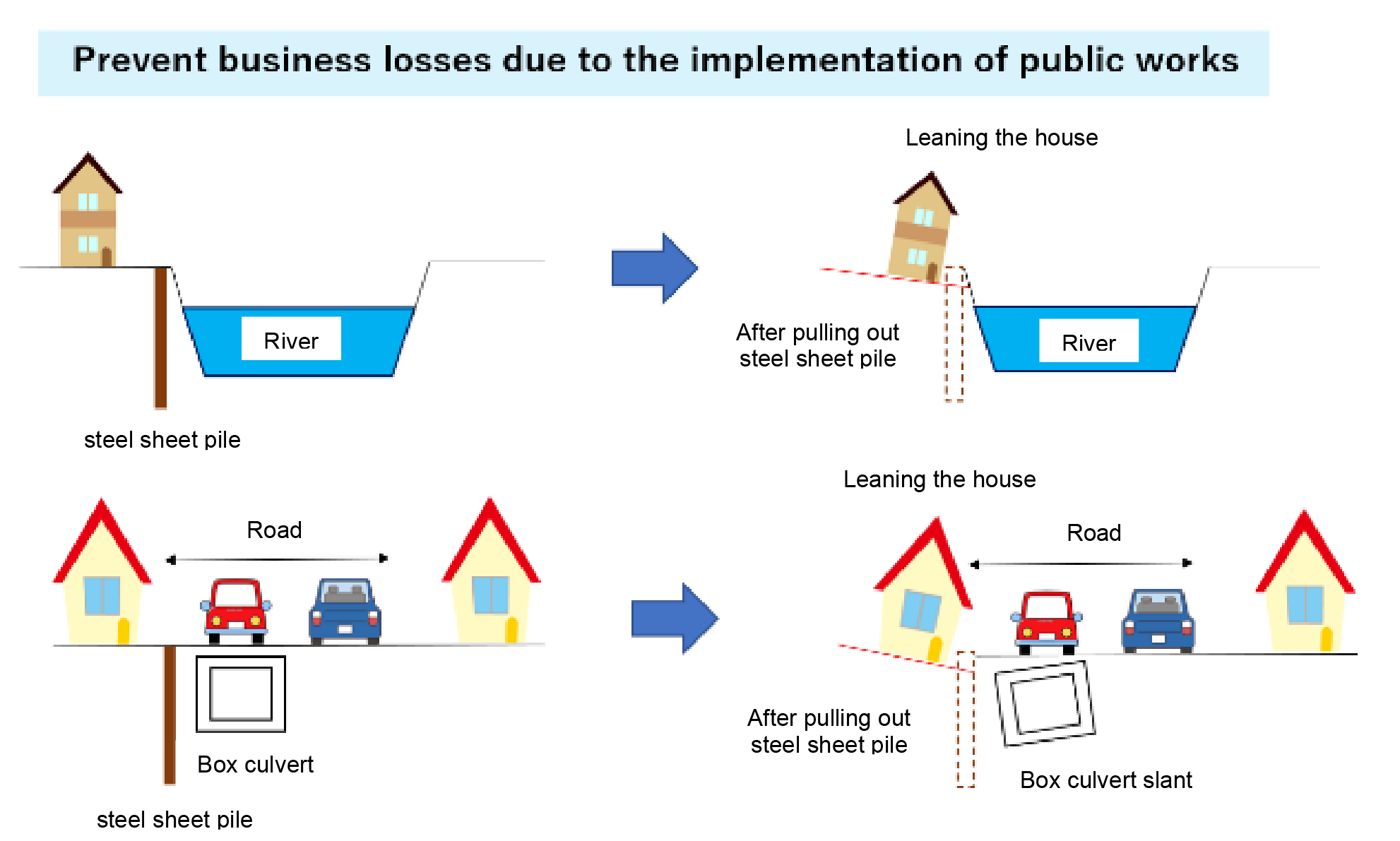

3.2.1 Reduction of CO2 Emissions from Reconstructing Public Facilities due to Ground Subsidence

If necessary, ground subsidence measures are not taken, and steel sheet piles are extracted, causing ground subsidence, reconstruction or repair of buildings and public facilities may be required, leading to CO2 emissions related to the construction. By comparing this scenario with the application of this method, where ground subsidence does not occur, the energy required for reconstruction is unnecessary, contributing to the reduction of related CO2 emissions.

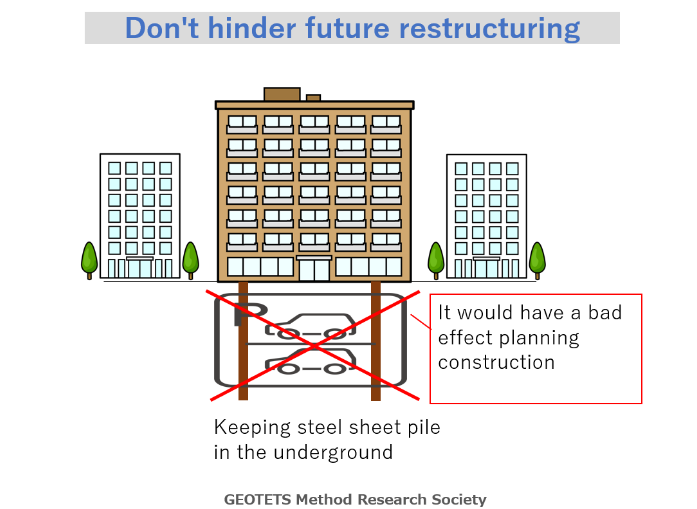

3.2.2 Reduction of CO2 Emissions during New Underground Space Planning

Leaving steel materials such as steel sheet piles in the ground can become obstacles during future underground space utilization. On the other hand, the low-density wall body (N value 20) left in the ground by the GEOTETS method has hardness similar to the surrounding soil, not becoming an obstacle during new underground space planning. This eliminates the need for energy to remove steel sheet piles during future underground space utilization, resulting in a reduction of related CO2 emissions. Additionally, extracting piles buried in underground spaces such as roads and buildings can remove constraints on future underground space facility planning, enabling efficient planning and space utilization. Overall, the reuse of steel sheet piles reduces unnecessary energy consumption, prevents building damage, and promotes effective underground space utilization, making it a valuable initiative towards SDGs (Fig.3 and Fig. 4).

4. New Initiatives for Sustainability (SDGs)

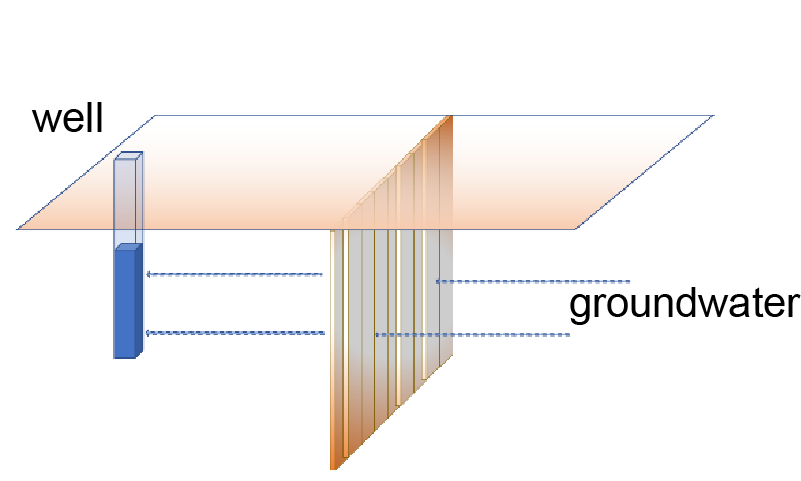

4.1 Research on Permeable GEO Walls

The continuous low-density cement walls left in the ground by this method have water-blocking properties due to the cement content, potentially obstructing the flow of water in the surrounding soil. Currently, in such project areas (e.g., river areas), permeability is ensured by setting extraction points where this method is not applied, in consultation with the project owner.

In contrast, research is underway to develop wall materials that have permeability equivalent to the surrounding soil while maintaining the early solidification and strength (N value 20) of this method. Achieving both permeability and strength is challenging due to their trade-off relationship, but development is progressing, including ensuring workability.

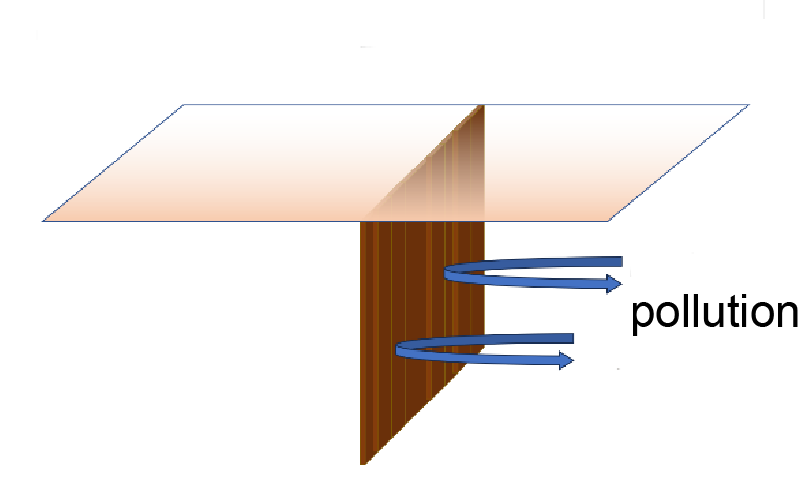

4.2 Research on Water-Blocking GEO Walls

On the other hand, the water-blocking properties of walls created by this method are also effective in preventing the spread of underground contaminants to the surrounding ground. Research is ongoing to further enhance this function. Although there are many challenges, such as wall continuity, thickness, and earthquake adaptability, this method significantly reduces costs compared to traditional large-scale diffusion prevention facilities, and steel sheet piles can be reused repeatedly. As a countermeasure against salt damage to coastal farmland, it is highly anticipated to ensure sustainability from the perspective of farmland conservation. (Fig.6)

5. Remarks

The GEOTETS method represents a significant advancement in sustainable construction practices. By addressing the challenges associated with the reuse of steel sheet piles and reducing CO2 emissions, it contributes to the broader goals of carbon neutrality and resource efficiency. Continued research and development in this area will further enhance the method's effectiveness and expand its applications, supporting the construction industry's transition towards a more sustainable future.

References

Interview Report A novel pile extraction method: The best practical use of the GEOTETS Method.

| << Previous | Newsletter Top | Next >> |